Page 385 - IJB-9-6

P. 385

International Journal of Bioprinting Biomimetic biofabrication of tumors volume

On the other hand, synthetic polymers such as with precise size and controlled architecture. Moreover, 3D

polyethylene glycol (PEG) are able to form hydrogels bioprinting enables the construction of tissue models in a

with tunable mechanical properties, such as stiffness or high-throughput manner, which is indispensable to meet

degradation rate, but often lack the ability to recapitulate the need for more reliable and standardized models for

the native ECM due to the absence of any motif for cell anti-cancer drug screening .

[17]

adhesion. However, synthetic polymers can be engineered

by chemical functionalization with various bioactive Indeed, during the last decade, researchers have

moieties, such as integrin-binding or enzymatically attempted to reproduce the complexity of the tumor milieu

degradable (e.g., MMP-cleavable) peptide sequences, to via 3D bioprinting, building biomimetic 3D in vitro tumor

enhance the ultimate functionality. models. Taken together, the capability of using multiple cell

types (including all the elements that make up the TME)

Harnessing the advantages of blending naturally and different biomaterials, along with the possibility to

derived and synthetic materials, composite inks are develop a functional vascularization, made 3D bioprinting

preferred for the fabrication of biomimetic TME models. an attractive and promising strategy to engineer 3D in vitro

Nevertheless, the combination of tissue type, material tumor models.

ink, and bioprinting technology has offered a challenging

choice over the possibility of printing functional cancerous In the following section, the main 3D bioprinting

models de novo. techniques are briefly described, followed by the discussion

of the more relevant studies on the development of

3.2. 3D bioprinting of tumor microenvironments 3D-bioprinted models that resemble various TMEs and

3D bioprinting is a revolutionizing technique in which their main features, classified by the bioprinting technique

3D structures are fabricated via layer-by-layer deposition employed (Figure 3).

of biomaterials, living cells, and biomolecules for tissue

engineering and regenerative medicine purposes . 3.2.1. Inkjet-based bioprinting

[9]

Typically, 3D bioprinting offers several advantages, such as Inkjet-based bioprinting (IBB) is a non-contact 3D

[46]

the ability to provide high control over spatial and temporal printing technology that allows for the positioning of

deposition of cells, alongside the fabrication of structures cells and biomaterials into a desired pattern using small

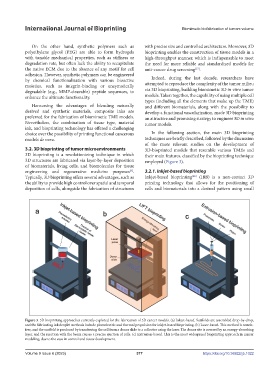

Figure 3. 3D bioprinting approaches currently explored for the fabrication of 3D cancer models. (a) Inkjet-based. Scaffolds are assembled drop-by-drop,

and the fabricating ink droplet methods include piezoelectric and thermal propulsion for inkjet-based bioprinting. (b) Laser-based. This method is nozzle-

free, and the scaffold is produced by transferring the cell from a donor slide to a collector using the laser. The donor site is covered by an energy-absorbing

layer, and the reaction with the beam causes a precise ejection of cells. (c) Extrusion-based. This is the most widespread bioprinting approach in cancer

modeling, due to the ease in control and tissue development.

Volume 9 Issue 6 (2023) 377 https://doi.org/10.36922/ijb.1022