Page 25 - MSAM-1-2

P. 25

Materials Science in Additive Manufacturing Laser absorption and printability of 90W-Ni-Fe

A

B

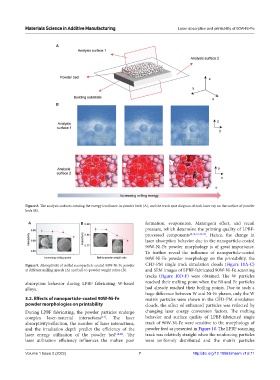

Figure 8. The analysis surfaces creating the energy irradiance in powder beds (A), and the track spot diagram of each laser ray on the surface of powder

beds (B).

A B formation, evaporation, Marangoni effect, and recoil

pressure, which determine the printing quality of LPBF-

processed components [8,14,22,24,25] . Hence, the change in

laser absorption behavior due to the nanoparticle-coated

90W-Ni-Fe powder morphology is of great importance.

To further reveal the influence of nanoparticle-coated

90W-Ni-Fe powder morphology on the printability, the

Figure 9. Absorptivity of milled nanoparticle-coated 90W-Ni-Fe powder CFD-PM single track simulation clouds (Figure 10A-C)

at different milling speeds (A) and ball-to-powder weight ratios (B). and SEM images of LPBF-fabricated 90W-Ni-Fe scanning

tracks (Figure 10D-F) were obtained. The W particles

absorption behavior during LPBF fabricating W-based reached their melting point when the Ni and Fe particles

alloys. had already reached their boiling points. Due to such a

huge difference between W and Ni-Fe phases, only the W

3.2. Effects of nanoparticle-coated 90W-Ni-Fe matrix particles were shown in the CFD-PM simulation

powder morphologies on printability clouds, the effect of enhanced particles was reflected by

During LPBF fabricating, the powder particles undergo changing laser energy conversion factors. The melting

complex laser-material interactions . The laser behavior and surface quality of LPBF-fabricated single

[13]

absorptivity/reflection, the number of laser interactions, track of 90W-Ni-Fe were sensitive to the morphology of

and the irradiation depth predict the efficiency of the powder feed as presented in Figure 10. The LPBF scanning

laser energy utilization of the powder bed [14,22] . The track was relatively straight when the reinforcing particles

laser utilization efficiency influences the molten pool were uniformly distributed and the matrix particles

Volume 1 Issue 2 (2022) 7 http://doi.org/10.18063/msam.v1i2.11