Page 38 - MSAM-2-3

P. 38

Materials Science in Additive Manufacturing Cast and 3D-printed fiber orientations

A B

C D

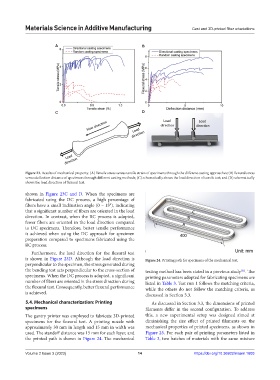

Figure 23. Results of mechanical property: (A) Tensile stress versus tensile strain of specimens through the different casting approaches; (B) flexural stress

versus deflection distance of specimens through different casting methods; (C) schematically shows the load direction of tensile test; and (D) schematically

shows the load direction of flexural test.

shown in Figure 23C and D. When the specimens are

fabricated using the DC process, a high percentage of

fibers have a small inclination angle (0 – 15°), indicating

that a significant number of fibers are oriented in the load

direction. In contrast, when the RC process is adopted,

fewer fibers are oriented in the load direction compared

to DC specimens. Therefore, better tensile performance

is achieved when using the DC approach for specimen

preparation compared to specimens fabricated using the

RC process.

Furthermore, the load direction for the flexural test

is shown in Figure 23D. Although the load direction is Figure 24. Printing path for specimens of the mechanical test.

perpendicular to the specimen, the stress generated during

the bending test acts perpendicular to the cross-section of testing method has been stated in a previous study . The

[31]

specimens. When the DC process is adopted, a significant printing parameters adopted for fabricating specimens are

number of fibers are oriented in the stress direction during listed in Table 3. Test run 1 follows the matching criteria,

the flexural test. Consequently, better flexural performance while the others do not follow the matching criteria, as

is achieved. discussed in Section 3.3.

5.4. Mechanical characterization: Printing As discussed in Section 3.3, the dimensions of printed

specimens filaments differ in the second configuration. To address

The gantry printer was employed to fabricate 3D-printed this, a new experimental setup was designed aimed at

specimens for the flexural test. A printing nozzle with diminishing the size effect of printed filaments on the

approximately 30 mm in length and 15 mm in width was mechanical properties of printed specimens, as shown in

used. The standoff distance was 15 mm for each layer, and Figure 25. For each pair of printing parameters listed in

the printed path is shown in Figure 24. The mechanical Table 3, two batches of materials with the same mixture

Volume 2 Issue 3 (2023) 14 https://doi.org/10.36922/msam.1603