Page 88 - MSAM-2-3

P. 88

Materials Science in Additive Manufacturing Functional graded and hybrid TPMS lattices

A B

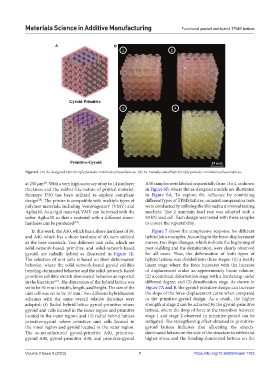

Figure 6. (A) As-designed hybrid triply periodic minimal surfaces lattices. (B) As-manufactured hybrid triply periodic minimal surfaces lattices.

[6]

at 250 µm . With a very high accuracy of up to 14 µm layer A30 samples were labeled sequentially from 1 to 4, as shown

thickness and the rubber-like nature of printed material, in Figure 6B, where the as-designed models are illustrated

Stratasys J750 has been utilized to explore compliant in Figure 6A. To explore the influence by combining

[28]

design . The printer is compatible with multiple types of different types of TPMS lattices, uniaxial compression tests

polymer materials, including VeroMagentaV (VMV) and were conducted by utilizing the Shimadzu universal testing

Agilus30. As a rigid material, VMV can be mixed with the machine. The 2 mm/min load rate was adopted with a

softer Agilus30 so that a material with a different shore- 50 kN load cell. Each design was tested with three samples

[29]

hardness can be produced . to ensure the repeatability.

In this work, the A30, which has a shore hardness of 30, Figure 7 shows the compressive response for different

and A40, which has a shore hardness of 40, were utilized hybrid lattice samples. According to the force-displacement

as the base materials. Two different unit cells, which are curves, two slope changes, which indicate the beginning of

solid-network-based primitive and solid-network-based post-yielding and the densification, were clearly observed

gyroid, are radially hybrid as illustrated in Figure 1E. for all cases. Thus, the deformation of both types of

The selection of unit cells is based on their deformation hybrid lattices was divided into three stages: (1) a nearly

behavior, where the solid-network-based gyroid exhibits linear stage where the force increases with the increase

bending-dominated behavior and the solid-network-based of displacement under an approximately linear relation;

primitive exhibits stretch-dominated behavior as reported (2) a continual deformation stage with a hardening under

[23]

in the literature . The dimension of the hybrid lattice was different degree; and (3) densification stage. As shown in

set to be 50 mm in width, length, and height. The size of the Figure 7A and B, the gyroid-primitive design can increase

unit cell was set to be 10 mm. Two different hybridization the slope of the force-displacement curve when compared

schemes with the same overall relative densities were to the primitive-gyroid design. As a result, the higher

adopted: (i) Radial hybrid lattice gyroid-primitive where strength at stage 2 can be achieved by the gyroid-primitive

gyroid unit cells located in the inner region and primitive lattices, where the drop of force at the transition between

located in the outer region; and (ii) radial hybrid lattices stage 1 and stage 2 observed in primitive-gyroid can be

primitive-gyroid where primitive unit cells located in mitigated. The strengthening effect obtained in primitive-

the inner region and gyroid located in the outer region. gyroid lattices indicates that allocating the stretch-

The as-manufactured gyroid-primitive A40, primitive- dominated lattices on the side of the structure to withstand

gyroid A40, gyroid-primitive A30, and primitive-gyroid higher stress and the bending-dominated lattices on the

Volume 2 Issue 3 (2023) 7 https://doi.org/10.36922/msam.1753