Page 89 - MSAM-3-1

P. 89

Materials Science in Additive Manufacturing Bioactive hydrogels for 3D bioprinting

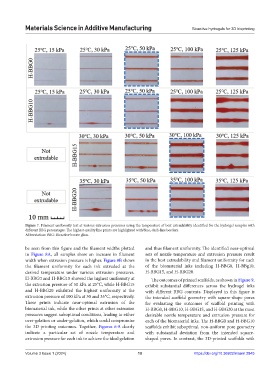

Figure 7. Filament uniformity test at various extrusion pressures using the temperature of best extrudability identified for the hydrogel samples with

different BBG percentages. The highest-quality line prints are highlighted with blue, dash-line borders.

Abbreviation: BBG: Bioactive borate glass.

be seen from this figure and the filament widths plotted and thus filament uniformity. The identified near-optimal

in Figure 8A, all samples show an increase in filament sets of nozzle temperature and extrusion pressure result

width when extrusion pressure is higher. Figure 8B shows in the best extrudability and filament uniformity for each

the filament uniformity for each ink extruded at the of the biomaterial inks including H-BBG0, H-BBg10,

desired temperature under various extrusion pressures. H-BBG15, and H-BBG20.

H-BBG0 and H-BBG10 showed the highest uniformity at The outcomes of printed scaffolds, as shown in Figure 9,

the extrusion pressure of 50 kPa at 25°C, while H-BBG15 exhibit substantial differences across the hydrogel inks

and H-BBG20 exhibited the highest uniformity at the with different BBG contents. Displayed in this figure is

extrusion pressure of 100 kPa at 30 and 35°C, respectively. the intended scaffold geometry with square-shape pores

These prints indicate near-optimal extrusion of the for evaluating the outcomes of scaffold printing with

biomaterial ink, while the other prints at other extrusion H-BBG0, H-BBG10, H-BBG15, and H-BBG20 at the most

pressures suggest suboptimal conditions, leading to either desirable nozzle temperature and extrusion pressure for

over-gelation or under-gelation, which could compromise each of the biomaterial inks. The H-BBG0 and H-BBG10

the 3D printing outcomes. Together, Figures 6-8 clearly scaffolds exhibit suboptimal, non-uniform pore geometry

indicate a particular set of nozzle temperature and with substantial deviation from the intended square-

extrusion pressure for each ink to achieve the ideal gelation shaped pores. In contrast, the 3D-printed scaffolds with

Volume 3 Issue 1 (2024) 10 https://doi.org/10.36922/msam.2845