Page 120 - MSAM-4-3

P. 120

Materials Science in Additive Manufacturing Sustainable manufacturing composite material optimization

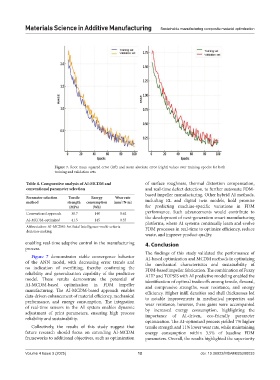

Figure 7. Root mean squared error (left) and mean absolute error (right) values over training epochs for both

training and validation sets

Table 4. Comparative analysis of AI‑MCDM and of surface roughness, thermal distortion compensation,

conventional parameter selection and real-time defect detection, to further automate FDM-

based impeller manufacturing. Other hybrid AI methods,

Parameter selection Tensile Energy Wear rate

method strength consumption (mm /N·m) including RL and digital twin models, hold promise

3

(MPa) (Wh) for predicting machine-specific variations in FDM

Conventional approach 38.7 140 0.62 performance. Such advancements would contribute to

AI-MCDM-optimized 41.5 145 0.55 the development of next-generation smart manufacturing

platforms, where AI systems continually learn and evolve

Abbreviation: AI-MCDM: Artificial Intelligence–multi-criteria FDM processes in real-time to optimize efficiency, reduce

decision-making.

waste, and improve product quality.

enabling real-time adaptive control in the manufacturing 4. Conclusion

process.

The findings of this study validated the performance of

Figure 7 demonstrates stable convergence behavior AI-based optimization and MCDM methods in optimizing

of the ANN model, with decreasing error trends and the mechanical characteristics and sustainability of

no indication of overfitting, thereby confirming the FDM-based impeller fabrication. The combination of Fuzzy

reliability and generalization capability of the predictive AHP and TOPSIS with AI predictive modeling enabled the

model. These results demonstrate the potential of identification of optimal trade-offs among tensile, flexural,

AI-MCDM-based optimization in FDM impeller and compressive strengths, wear resistance, and energy

manufacturing. The AI-MCDM-based approach enables efficiency. Higher infill densities and shell thicknesses led

data-driven enhancement of material efficiency, mechanical to notable improvements in mechanical properties and

performance, and energy consumption. The integration wear resistance; however, these gains were accompanied

of real-time sensors in the AI system enables dynamic by increased energy consumption, highlighting the

adjustment of print parameters, ensuring high process importance of AI-driven, eco-friendly parameter

reliability and sustainability.

optimization. The AI-optimized process yielded 7% higher

Collectively, the results of this study suggest that tensile strength and 11% lower wear rate, while maintaining

future research should focus on extending AI-MCDM energy consumption within 3.5% of baseline FDM

frameworks to additional objectives, such as optimization parameters. Overall, the results highlighted the superiority

Volume 4 Issue 3 (2025) 12 doi: 10.36922/MSAM025200033