Page 61 - manuscript_ijb05590

P. 61

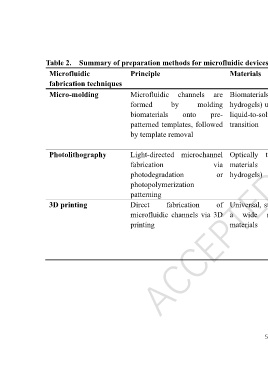

Table 2. Summary of preparation methods for microfluidic devices.

Microfluidic Principle Materials Advantages Limits

fabrication techniques

Micro-molding Microfluidic channels are Biomaterials (e.g., ·Low technical requirements ·Geometric limitations

formed by molding hydrogels) undergoing ·Excellent for prototyping ·Mold Cost Constraints

biomaterials onto pre- liquid-to-solid phase elementary microphysiological

patterned templates, followed transition scaffolds

by template removal ·Requires only basic laboratory

equipment

Photolithography Light-directed microchannel Optically transparent ·Enables fabrication of arbitrary, ·Requires a trade-off

fabrication via materials (e.g., complex microfluidic between patterning

photodegradation or hydrogels) architectures resolution and fabrication

photopolymerization ·Pattern formation is no longer speed

patterning restricted to material surfaces

3D printing Direct fabrication of Universal, suitable for ·Spatial multifunctionality ·3D printing technologies

microfluidic channels via 3D a wide range of (enabled by unconstrained 3D exhibit inferior resolution

printing materials nozzle mobility) compared to micro-

molding or

photolithography

techniques

59