Page 63 - manuscript_ijb05590

P. 63

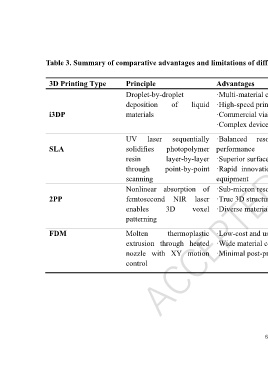

Table 3. Summary of comparative advantages and limitations of different 3D printing types

3D Printing Type Principle Advantages Limitations

Droplet-by-droplet ·Multi-material capability ·Limited material

deposition of liquid ·High-speed printing selection ·

i3DP materials ·Commercial viability ·Challenges in droplet optimization

·Complex device fabrication ·Resolution-speed tradeoff

UV laser sequentially ·Balanced resolution, cost and ·Resolution constrained by optical hardware and

SLA solidifies photopolymer performance resin properties

resin layer-by-layer ·Superior surface finish ·Challenges in uncured resin removal

through point-by-point ·Rapid innovation in materials and ·Single-material limitation per print

scanning equipment

Nonlinear absorption of ·Sub-micron resolution (<1 μm) ·Extremely slow process

2PP femtosecond NIR laser ·True 3D structuring capability ·High equipment costs

enables 3D voxel ·Diverse material options ·Cleanroom requirements

patterning ·Difficult for enclosed microfluidics

FDM Molten thermoplastic ·Low-cost and user-friendly ·Poor surface finish

extrusion through heated ·Wide material compatibility ·Poor Z-axis mechanical strength

nozzle with XY motion ·Minimal post-processing ·Low dimensional accuracy (200-500 μm features)

control ·Slow printing speed

60