Page 49 - ESAM-1-2

P. 49

Engineering Science in

Additive Manufacturing Multi-material additive manufacturing of metals

A B

C D

E

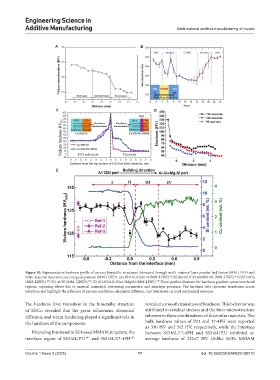

Figure 10. Representative hardness profile of various bimetallic structures fabricated through multi-material laser powder bed fusion (MM-LPBF) and

multi-material laser-directed energy deposition (MM-LDED): (A) SS316L/CuSn10 (MM-LPBF); (B) SS316L/C25400/SS316L (MM-LPBF); (C)H13/Cu

56

58

167

172

(MM-LDED); (D) Al/W (MM- LDED); (E) Al12Si/Al3.5Cu1.5Mg1Si (MM-LPBF). These profiles illustrate the hardness gradient across interfacial

177

regions, capturing effects due to material mismatch, processing parameters, and interlayer presence. The hardness data represent transitions across

interfaces and highlight the influence of process conditions, elemental diffusion, and interlayers on local mechanical response.

The hardness level transition in the bimetallic structure revealed a smooth transition of hardness. This behavior was

of SS/Cu revealed that the grain refinement, elemental attributed to residual stresses and the finer microstructure

diffusion, and strain hardening played a significant role in inherent to these combinations of dissimilar materials. The

the hardness of the components. bulk hardness values of P21 and 17-4PH were reported

as 330 HV and 312 HV, respectively, while the interface

Extending this trend to SS-based MMAM structure, the between SS316L/17-4PH and SS316L/P21 exhibited an

interface region of SS316L/P21 and SS316L/17-4PH average hardness of 232±7 HV. Unlike SS/Fe MMAM

141

147

Volume 1 Issue 2 (2025) 17 doi: 10.36922/ESAM025180010