Page 428 - IJB-10-1

P. 428

International Journal of Bioprinting Mechanically biomimicking 3D bone model

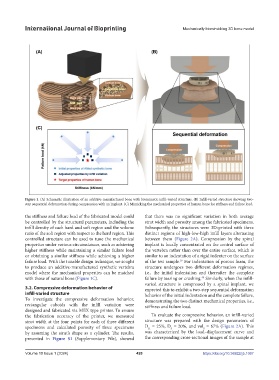

Figure 1. (A) Schematic illustration of an additive-manufactured bone with biomimetic infill-varied structure. (B) Infill-varied structure showing two-

step sequential deformation during compression with an implant. (C) Mimicking the mechanical properties of human bone for stiffness and failure load.

the stiffness and failure load of the fabricated model could that there was no significant variation in both average

be controlled by the structural parameters, including the strut width and porosity among the fabricated specimens.

infill density of each hard and soft region and the volume Subsequently, the structures were 3D-printed with three

ratio of the soft region with respect to the hard region. This distinct regions of high-low-high infill layers alternating

controlled structure can be used to tune the mechanical between them (Figure 2A). Compression by the spinal

properties under various circumstances, such as achieving implant is locally concentrated on the central surface of

higher stiffness while maintaining a similar failure load the vertebra rather than over the entire surface, which is

or obtaining a similar stiffness while achieving a higher similar to an indentation of a rigid indenter on the surface

failure load. With the tunable design technique, we sought of the test sample. For indentation of porous foam, the

39

to produce an additive-manufactured synthetic vertebra structure undergoes two different deformation regimes,

model where the mechanical properties can be matched i.e., the initial indentation and thereafter the complete

with those of natural bone (Figure 1C). failure by tearing or crushing. Similarly, when the infill-

40

varied structure is compressed by a spinal implant, we

3.2. Compressive deformation behavior of expected this to exhibit a two-step sequential deformation

infill-varied structure behavior of the initial indentation and the complete failure,

To investigate the compressive deformation behavior, demonstrating the two distinct mechanical properties, i.e.,

rectangular cuboids with the infill variation were stiffness and failure load.

designed and fabricated via MEX type printer. To ensure

the fabrication accuracy of the printer, we measured To evaluate the compressive behavior, an infill-varied

strut width at the four points for each of three different structure was prepared with the design parameters of

specimens and calculated porosity of three specimens D = 25%, D = 20%, and vol = 67% (Figure 2A). This

S

H

S

by assuming the strut’s shape as a cylinder. The results, was characterized by the load–displacement curve and

presented in Figure S1 (Supplementary File), showed the corresponding cross-sectional images of the sample at

Volume 10 Issue 1 (2024) 420 https://doi.org/10.36922/ijb.1067