Page 502 - IJB-10-1

P. 502

International Journal of Bioprinting Macro and micro structure of a 3D-printed implant

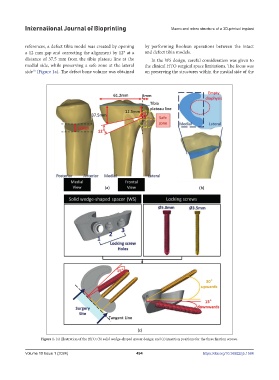

references, a defect tibia model was created by opening by performing Boolean operations between the intact

a 12 mm gap and correcting the alignment by 12° at a and defect tibia models.

distance of 37.5 mm from the tibia plateau line at the In the WS design, careful consideration was given to

medial side, while preserving a safe zone at the lateral the clinical HTO surgical space limitations. The focus was

10

side (Figure 1a). The defect bone volume was obtained on preserving the structures within the medial side of the

Figure 1. (a) Illustration of the HTO; (b) solid wedge-shaped spacer design; and (c) insertion positions for the three fixation screws.

Volume 10 Issue 1 (2024) 494 https://doi.org/10.36922/ijb.1584