Page 506 - IJB-10-1

P. 506

International Journal of Bioprinting Macro and micro structure of a 3D-printed implant

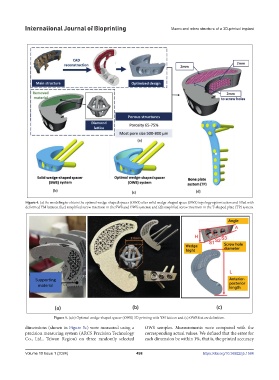

Figure 4. (a) Re-modeling to obtain the optimal wedge-shaped spacer (OWS) after solid wedge-shaped space (SWS) topology optimization and filled with

deformed YM lattices; (b,c) simplified screw insertion in the SWS and OWS systems; and (d) simplified screw insertion in the T-shaped plate (TP) system.

Figure 5. (a,b) Optimal wedge-shaped spacer (OWS) 3D printing with YM lattices and (c) OWS feature definition.

dimensions (shown in Figure 5c) were measured using a OWS samples. Measurements were compared with the

precision measuring system (ARCS Precision Technology corresponding actual values. We defined that the error for

Co., Ltd., Taiwan Region) on three randomly selected each dimension be within 1%, that is, the printed accuracy

Volume 10 Issue 1 (2024) 498 https://doi.org/10.36922/ijb.1584