Page 84 - IJB-3-1

P. 84

Influence of electrohydrodynamic jetting parameters on the morphology of PCL scaffolds

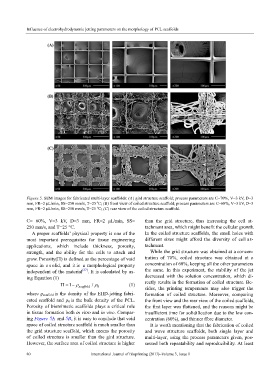

Figure 5. SEM images for fabricated multi-layer scaffolds: (A) gird structure scaffold; process parameters are C=70%, V=3 kV, D=3

o

mm, FR=2 μL/min, SS=250 mm/s, T=25 C; (B) front view of coiled structure scaffold; process parameters are C=60%, V=3 kV, D=3

o

mm, FR=2 μL/min, SS=250 mm/s, T=25 C; (C) rear view of the coiled structure scaffold.

C= 60%, V=3 kV, D=3 mm, FR=2 μL/min, SS= than the grid structure, thus increasing the cell at-

250 mm/s, and T=25 °C. tachment area, which might benefit the cellular growth.

A proper scaffolds’ physical property is one of the In the coiled structure scaffolds, the small holes with

most important prerequisites for tissue engineering different sizes might afford the diversity of cell a t-

applications, which include thickness, porosity, tachment.

strength, and the ability for the cells to attach and While the grid structure was obtained at a concen-

grow. Porosity(Π) is defined as the percentage of void tration of 70%, coiled structure was obtained at a

space in a s olid, and it is a morphological property concentration of 60%, keeping all the other parameters

independent of the material [27] . It is calculated by us- the same. In this experiment, the stability of the jet

ing Equation (1) decreased with the solution concentration, which di-

1 scaffold / ρΠ= − ρ 0 (1) rectly results in the formation of coiled structure. Be-

sides, the printing temperature may also trigger the

where ρ scaffold is the density of the EHD-jetting fabri- formation of coiled structure. Moreover, comparing

cated scaffold and ρ 0 is the bulk density of the PCL. the front view and the rear view of the coiled scaffolds,

Porosity of biomimetic scaffolds plays a critical role the first layer was flattened, and the reasons might be

in tissue formation both in vitro and in vivo. Compar- insufficient time for solidification due to the low con-

ing Figure 5A and 5B, it is easy to conclude that void centration (60%), and thinner fibre diameter.

space of coiled structure scaffold is much smaller than It is worth mentioning that the fabrication of coiled

the grid structure scaffold, which means the porosity and wave structure scaffolds, both single layer and

of coiled structure is smaller than the gird structure. multi-layer, using the process parameters given, pos-

However, the surface area of coiled structure is higher sessed both repeatability and reproducibility. At least

80 International Journal of Bioprinting (2017)–Volume 3, Issue 1