Page 395 - IJB-10-3

P. 395

International Journal of Bioprinting Optimizing 3D-printed mouthguards

Table 3. Fisher analysis of the broken result of three types of MG samples during mid-fatigue test

MG groups Broken (%) Unbroken (%) χ value P-value

2

Conventional MGs (n = 6) 0 (0.0) 6 (100.0) 24.39 <0.001

Single-layer additively manufactured MGs (n = 9) 9 (100) 0 (0.0)

Double-layer additively manufactured MGs (n = 9) 0 (0.0) 9 (100.0)

Table 4. Retention force for each sample in each fatigue test stage

Retention force (N)

Fatigue test stages

Pre Mid Post

ERK MGs 29.0 ± 2.2 37.4 ± 4.2 34.9 ± 9.4

MG21 MGs 33.0 ± 4.7 42.7 ± 3.1 44.0 ± 4.4

D-A30 MGs 5.7 ± 0.6 5.4 ± 0.3 4.9 ± 0.1

D-A50 MGs 5.9 ± 0.4 5.9 ± 0.0 7.4 ± 0.3

D-A70 MGs 6.9 ± 0.2 9.5 ± 0.4 8.6 ± 1.5

MG21: P < 0.043 pre v. post.

Pre-fatigue: P < 0.001 ERK, MG21 v. D-A all MGs

Mid-fatigue: P < 0.001 ERK, MG21 v. D-A all MGs

Post-fatigue: P < 0.001 ERK, MG21 v. D-A all MGs

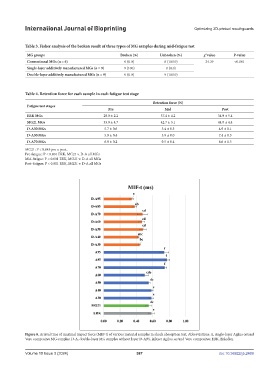

Figure 8. Arrival time of maximal impact force (MIF-t) of various material samples in shock absorption test. Abbreviations: A, single-layer Agilus or/and

Vero composites MG samples; D-A, double-layer MG samples without layer D-ABS, inlayer Agilus, or/and Vero composites; ERK, Erkoflex.

Volume 10 Issue 3 (2024) 387 doi: 10.36922/ijb.2469