Page 418 - IJB-10-3

P. 418

International Journal of Bioprinting Expanding 3D cell proliferation with DLP bioprinting

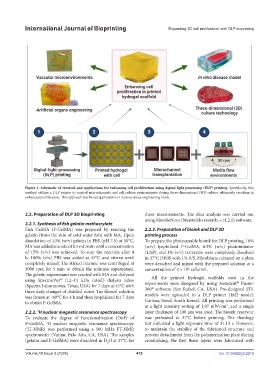

Figure 1. Schematic of research and applications for enhancing cell proliferation using digital light processing (DLP) printing. Specifically, this

method utilizes a DLP printer to control microchannels and cell culture environments during three-dimensional (3D) culture, ultimately resulting in

enhanced proliferation. This approach has broad applications in various tissue engineering fields.

2.2. Preparation of DLP 3D bioprinting these measurements. The data analysis was carried out

using MestReNova (Mestrelab research, v14.2.1) software.

2.2.1. Synthesis of fish gelatin methacrylate

Fish GelMA (F-GelMA) was prepared by reacting the 2.2.3. Preparation of bioink and DLP 3D

gelatin (from the skin of cold-water fish) with MA. Upon printing process

dissolution of 10% (w/v) gelatin in PBS (pH 7.5) at 50°C, To prepare the photocurable bioink for DLP printing, 10%

MA was added at a rate of 0.5 mL/min until a concentration (w/v) lyophilized F-GelMA, 0.5% (w/v) photoinitiator

of 15% (v/v) was achieved. To stop the reaction after 4 (LAP), and 1% (v/v) tartrazine were completely dissolved

h, 100% (v/v) PBS was added at 45°C and stirred until in 37°C DPBS with 1% P/S. Fibroblasts cultured on a plate

completely mixed. The stirred mixture was centrifuged at were detached and mixed with the prepared solution at a

3000 rpm for 5 min to obtain the solution supernatant. concentration of 2 × 10 cells/mL.

6

The gelatin supernatant was reacted with MA and dialyzed All the printed hydrogel scaffolds used in the

using Spectra/Por (12–14 kDa cutoff) dialysis tubes experiments were designed by using Autodesk Fusion

®

®

(Spectra Laboratories, Texas, USA) for 7 days at 45°C with ®

three daily changes of distilled water. The filtered solution 360 software (San Rafael, CA, USA). Pre-designed STL

was frozen at -80°C for 4 h and then lyophilized for 7 days models were uploaded to a DLP printer (IM2 model;

to obtain F-GelMA. Carima, Seoul, South Korea). All printing was performed

at a light intensity setting of 1.97 mW/cm , and a single

2

2.2.2. H nuclear magnetic resonance spectroscopy layer thickness of 100 µm was used. The bioink reservoir

1

To evaluate the degree of functionalization (DoF) of was preheated to 37°C before printing. The rheology

F-GelMA, H nuclear magnetic resonance spectroscopy test indicated a light exposure time of 31.13 s. However,

1

( H-NMR) was performed using a 500 MHz FT-NMR to maintain the stability of the fabricated structure and

1

spectrometer (Varian, Palo Alto, CA, USA). The samples prevent detachment from the polymerization plate during

(gelatin and F-GelMA) were dissolved in D O at 37°C for crosslinking, the first three layers were fabricated with

2

Volume 10 Issue 3 (2024) 410 doi: 10.36922/ijb.2219