Page 51 - IJB-4-1

P. 51

3D Printing of hydrogel composite systems: Recent advances in technology for tissue engineering

alginate scaffolds increased. In vitro cellular response using (GelMA) or GelMA with hyaluronic acid methacrylate

pre-osteoblast cells exhibited that silica coated collagen/ (HAMA) on pure alginate or alginate/hydroxyapatite (HAp)

alginate scaffolds had higher value of proliferation and composites by 3D plotting [110] . Incorporation of hydroxyapatite

gene expression than pure hydrogel scaffolds. Wang et al. increased the elastic modulus of printed hydrogel composites

added various kinds of bioglass including polyphosphate and HAMA in GelMA hydrogels improved chondrogenesis.

2+

(polyP), polyP*Ca -complex, silica, and biosilica produced The polycaprolactone (PCL) and alginate were printed layer-

by sol-gel method in to alginate/gelatin/SaOS-2 bone cell by-layer with a multihead deposition system as shown in

hydrogels composites [108] . Each of the mixed pastes were (Figure 10A) [111] . These hydrogel composites combined

extruded by 3D bioplotter and results showed that the chondrocyte cells and transforming growth factor beta (TGF-

added polyP and biosilica increased the proliferation and beta) to mimic the properties of cartilage. PCL/alginate

mineralization of bone cells. scaffolds with TGF-beta showed higher cartilaginous ECM

4.2 Soft Tissue Engineering Application formation. In vivo test using dorsal subcutaneous zone of

nude mouse showed that the amounts of collagen fibers and

Cartilage is a kind of soft tissue, which is a complex cartilaginous tissue formation of chondrocyte encapsulated

structure composed of interstitial fluid, collagen and PCL/alginate scaffolds with TGF-beta were higher than other

chondrocytes. Cartilage tissue engineering has been control hydrogels. PCL was also used as composite material

widely investigated because the injured cartilage does not for cartilage tissue engineering applications [112] . Electrospun

heal or regenerate by itself [109] . Hydrogels are excellent PCL and fibrin/collagen hydrogel containing chondrocytes

alternatives for use in cartilage engineering since they are were fabricated layer by layer by hybrid inkjet printing/

highly hydrated with a cross-linked architecture that can electrospinning system. The printed hybrid composite scaffolds

be filled with cells. These hydrogels scaffolds can be easily showed higher tensile properties compared with each of the

prepared by 3D printing but their poor mechanical stability PCL and fibrin/collagen hydrogels alone. Printed chondrocytes

remains a big challenge. Therefore, many researchers have cells maintained more than 80% of viability in vitro and

put in efforts to overcome this limitation by mixing pure large amounts of collagen and glycosaminoglycans which

hydrogels and fillers. are similar to elastic cartilage were produced in vivo. In order

Bartnikowski fabricated multi-layered hydrogel com- to fabricate tough hydrogels for cartilage tissue engineering

posites comprising functionalized gelatin methacrylamide applications, agar was combined with alginate by Wei et

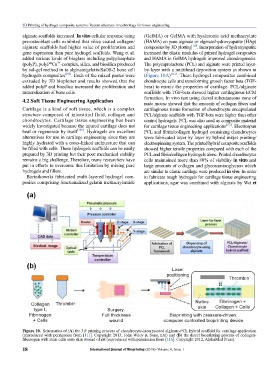

Figure 10. Schematics of (A) the 3D printing process of chondrocyte-incorporated alginate-PCL hybrid scaffold for cartilage application

(reproduced with permission from [111]. Copyright 2013, John Wiley & Sons, Ltd) and (B) the direct bioprinting process of collagen-

fibrinogen with stem cells onto skin wound of rat (reproduced with permission from [116]. Copyright 2012, AlphaMed Press).

18 International Journal of Bioprinting (2018)–Volume 4, Issue 1