Page 20 - IJB-4-2

P. 20

The arrival of commercial bioprinters – Towards 3D bioprinting revolution!

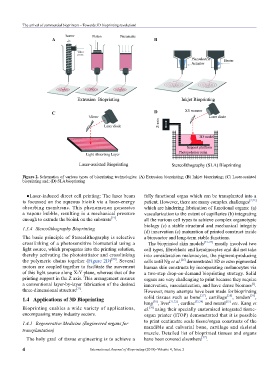

Figure 2. Schematics of various types of bioprinting technologies: (a) Extrusion bioprinting; (B) Inkjet bioprinting; (c) Laser-assisted

bioprinting and; (D) SLA bioprinting

●Laser-induced direct cell printing: The laser beam fully functional organ which can be transplanted into a

is focussed on the aqueous bioink via a laser-energy patient. However, there are many complex challenges [2,22]

absorbing membrane. This phenomenon generates which are hindering fabrication of functional organs: (a)

a vapour bubble, resulting in a mechanical pressure vascularization to the extent of capillaries (b) integrating

[19]

enough to extrude the bioink on the substrate . all the various cell types to achieve complex organotypic

biology (c) a stable structural and mechanical integrity

1.3.4 Stereolithography Bioprinting

(d) innervation (e) maturation of printed construct inside

The basic principle of Stereolithography is selective a bioreactor and long-term stable functions.

crosslinking of a photosensitive biomaterial using a The bioprinted skin models [23–25] mostly involved two

light source, which propagates into the printing solution, cell types, fibroblasts and keratinocytes and did not take

thereby activating the photoinitiator and crosslinking into consideration melanocytes, the pigment-producing

the polymeric chains together (Figure 2D) [20] . Several cells until Ng et al. demonstrated 3D in vitro pigmented

[26]

motors are coupled together to facilitate the movement human skin constructs by incorporating melanocytes via

of this light source along X-Y plane, whereas that of the a two-step drop-on-demand bioprinting strategy. Solid

printing support in the Z axis. This arrangement ensures organs are very challenging to print because they require

a conventional layer-by-layer fabrication of the desired innervation, vascularization, and have dense biomass .

[2]

[21]

three-dimensional structure . However, many attempts have been made for bioprinting

1.4 applications of 3D Bioprinting solid tissues such as bone [27] , cartilage [28] , tendon [29] ,

lung , liver [31,32] , cardiac [33,34] and neural etc. Kang et

[30]

[35]

Bioprinting enables a wide variety of applications, al. [36] using their specially customised integrated tissue-

encompassing many industry sectors. organ printer (ITOP) demonstrated that it is possible

1.4.1 Regenerative Medicine (Engineered organs for to print centimetre scale tissue/organ constructs of the

transplantation) mandible and calvarial bone, cartilage and skeletal

muscle. Detailed list of bioprinted tissues and organs

The holy grail of tissue engineering is to achieve a have been covered elsewhere .

[37]

4 International Journal of Bioprinting (2018)–Volume 4, Issue 2