Page 28 - IJB-4-2

P. 28

The arrival of commercial bioprinters – Towards 3D bioprinting revolution!

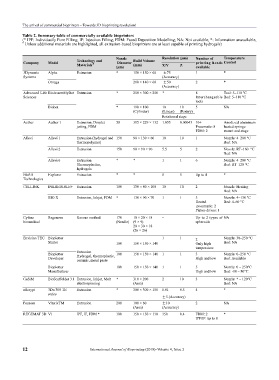

table 2. Summary table of commercially available bioprinters

(* IPF: Individually Pore Filling; IF: Injection Filling; FDM: Fused Deposition Modelling; NA: Not available; *: Information unavailable,

# Unless additional materials are highlighted, all extrusion-based bioprinters are at least capable of printing hydrogels)

technology and Nozzle Build volume Resolution (μm) Number of temperature

company Model # Diameter printing heads control

Materials (μm) (mm) X/Y Z available

3Dynamic Alpha Extrusion * 150 × 150 × 60 ±75 1 *

Systems (Accuracy)

Omega 210 × 140 × 60 ±50 2 *

(Accuracy)

Advanced Life BioAssemblyBot Extrusion * 250 × 300 × 250 * 8 Tool: 5–110 °C

Sciences Interchangeable Bed: 5–110 °C

tools

Biobot * 190 × 100 10 10 5 NA

(Cylinder) (Linear) (Rotary)

Rotational stage

Aether Aether 1 Extrusion, Droplet 50 315 × 229 × 132 1.055 0.00043 10+ Anodized aluminum

jetting, FDM Pneumatic: 8 heated syringe

FDM: 2 mount and stage

Allevi Allevi 1 Extrusion (hydrogel and 150 90 × 130 × 60 10 10 1 Nozzle: 4–200 °C

thermopolymer) Bed: NA

Allevi 2 Extrusion 150 90 × 90 × 90 5.5 5 2 Nozzle: RT–160 °C

Bed: NA

Allevi 6 Extrusion * * 1 1 6 Nozzle: 4–200 °C

Thermoplastics, Bed: RT–120 °C

hydrogels

Bio3D Explorer Extrusion * * 5 5 Up to 4 *

Technologies

CELLINK INKREDIBLE+ Extrusion 100 130 × 80 × 100 10 10 2 Nozzle: Heating

Bed: NA

BIO X Extrusion, Inkjet, FDM * 130 × 90 × 70 1 1 3 Nozzle: 4–130 °C

Heated Bed: 4–60 °C

pneumatic: 2

Piston-driven: 1

Cyfuse Regenova Kenzan method 170 10 × 20 × 18 – Up to 2 types of NA

biomedical (Needle) (9 × 9) spheroids

20 × 30 × 18

(26 × 26)

Envision TEC Bioplotter 1 1 2 Nozzle: 30–250 °C

Starter 100 150 × 150 × 140 Only high Bed: NA

temperature

Extrusion

Bioplotter Hydrogel, thermoplastic, 100 150 × 150 × 140 1 1 3 Nozzle: 0–250 °C

Developer High and low Bed: Available

ceramic, metal paste

Bioplotter 100 150 × 150 × 140 1 1 5 Nozzle: 0 – 250°C

Manufacturer High and low Bed: -10 – 80°C

GeSiM BioScaffolder 3.1 Extrusion, Inkjet, Melt * 310 × 200 2 10 3 Nozzle: * – 120°C

electrospinning (Area) Bed: NA

nScrypt 3Dn 300 TE Extrusion * 300 × 300 × 150 0.01 0.5 4 *

series

±5 (Accuracy)

Pensees VitarixTM Extrusion 200 100 × 60 ±10 2 NA

(Area) (Accuracy)

REGEMAT 3D V1 IPF, IF, FDM * 100 150 × 150 × 110 150 0.4 FDM: 2 *

IPF/IF: up to 8

12 International Journal of Bioprinting (2018)–Volume 4, Issue 2