Page 107 - IJB-5-2

P. 107

Lenoir L, et al.

manufacturing plan and the strategic choices. Finally, the Concerning microfluidic devices, Shin et al., reported

different methodologies propose a product improvement the development of a methodology to create an

phase. endothelialized network with a vascular geometry in a

biocompatible polymer, PDMS .

[19]

3.3. Manufacturing Process of Devices for Using photolithography, master molds were fabricated

Biological Application by etching the network pattern into silicon wafers. Closed

Only methodologies to design and manufacture a channels were created from silicon master molds by replica

product for biological application based on an initial molding of PDMS and subsequent plasma-bonding of a

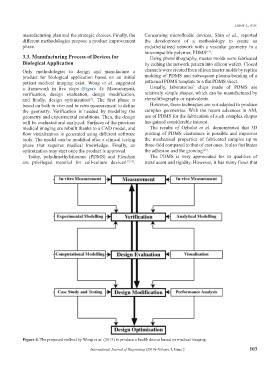

patient medical imaging exist. Wong et al. suggested patterned PDMS template to a flat PDMS sheet.

a framework in five steps (Figure 4): Measurement, Usually, laboratories’ chips made of PDMS are

verification, design evaluation, design modification, relatively simple shapes, which can be manufactured by

and finally, design optimization . The first phase is stereolithography or equivalents.

[8]

based on both in vivo and in vitro measurement to define However, these techniques are not adapted to produce

the geometry. Verification is needed by modeling the complex geometries. With the recent advances in AM,

geometry and experimental conditions. Then, the design use of PDMS for the fabrication of such complex shapes

will be evaluated and analyzed: Surfaces of the previous has gained considerable interest.

medical imaging are rebuilt thanks to a CAD model, and The results of Ozbolat et al. demonstrated that 3D

flow visualization is generated using different software printing of PDMS elastomers is possible and improves

tools. The model can be modified after a clinical testing the mechanical properties of fabricated samples up to

phase that requires medical knowledge. Finally, an three-fold compared to that of cast ones. It also facilitates

optimization may start once the product is approved. the adhesion and the growing .

[20]

Today, polydimethylsiloxane (PDMS) and Flexdym The PDMS is very appreciated for its qualities of

are privileged material for cell-culture devices [17,18] . translucent and rigidity. However, it has many flaws that

Figure 4. The proposed method by Wong et al. (2013) to produce a health device based on medical imaging.

International Journal of Bioprinting (2019)–Volume 5, Issue 2 103