Page 133 - IJB-10-6

P. 133

74

damage prediction by Chirianni et al. using the model (or Equation X) and the experimental

results reported by Han et al. (Scenario 1) and Li et al. (Scenario 2) for (B) printing with a given

75

73

nozzle diameter and various printing pressures, and (C) given printing pressure and various nozzle

diameter.

International Journal of Bioprinting Fluid mechanics of extrusion bioprinting

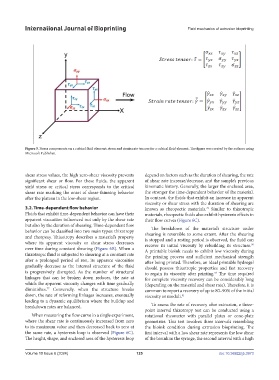

Figure 5. Stress components on a cubical fluid element; stress and strain rate tensors for a cubical

Figure 5. Stress components on a cubical fluid element; stress and strain rate tensors for a cubical fluid element. The figure was created by the authors using

Microsoft Publisher.

fluid element. The figure was created by the authors using Microsoft Publisher.

shear stress values, the high zero-shear viscosity prevents depend on factors such as the duration of shearing, the rate

significant shear or flow. For these fluids, the apparent of shear rate increase/decrease, and the sample’s previous

yield stress or critical stress corresponds to the critical kinematic history. Generally, the larger the enclosed area,

shear rate marking the onset of shear-thinning behavior the stronger the time-dependent behavior of the material.

after the plateau in the low-shear region. In contrast, the fluids that exhibit an increase in apparent

viscosity or shear stress with the duration of shearing are

3.2. Time-dependent flow behavior known as rheopectic materials. Similar to thixotropic

79

Fluids that exhibit time-dependent behavior can have their materials, rheopectic fluids also exhibit hysteresis effects in

apparent viscosities influenced not only by the shear rate their flow curves (Figure 6C).

but also by the duration of shearing. Time-dependent flow

behavior can be classified into two main types: thixotropy The breakdown of the material’s structure under

and rheopexy. Thixotropy describes a material’s property shearing is reversible to some extent. After the shearing

is stopped and a resting period is observed, the fluid can

where its apparent viscosity or shear stress decreases recover its initial viscosity by rebuilding its structure.

90

over time during constant shearing (Figure 6B). When a A printable bioink needs to exhibit low viscosity during

thixotropic fluid is subjected to shearing at a constant rate the printing process and sufficient mechanical strength

after a prolonged period of rest, its apparent viscosities after being printed. Therefore, an ideal printable hydrogel

gradually decrease as the internal structure of the fluid should possess thixotropic properties and fast recovery

is progressively disrupted. As the number of structural to regain its viscosity after printing. The time required

59

linkages that can be broken down reduces, the rate at for complete viscosity recovery can be considerably long

which the apparent viscosity changes with time gradually (depending on the material and shear rate). Therefore, it is

diminishes. Conversely, when the structure breaks common to report a recovery of up to 80–90% of the initial

77

down, the rate of reforming linkages increases, eventually 71 viscosity or moduli.

91

leading to a dynamic equilibrium where the buildup and

breakdown rates are balanced. To assess the rate of recovery after extrusion, a three-

point interval thixotropy test can be conducted using a

When measuring the flow curve in a single experiment, rotational rheometer with parallel plates or cone-plate

where the shear rate is continuously increased from zero geometries. This test involves three intervals resembling

to its maximum value and then decreased back to zero at the bioink condition during extrusion bioprinting. The

the same rate, a hysteresis loop is observed (Figure 6C). first interval with a low shear rate represents the low shear

The height, shape, and enclosed area of the hysteresis loop of the bioink in the syringe, the second interval with a high

Volume 10 Issue 6 (2024) 125 doi: 10.36922/ijb.3973