Page 334 - IJB-10-6

P. 334

International Journal of Bioprinting 3D-printed PPDO/GO stents for CHD treatment.

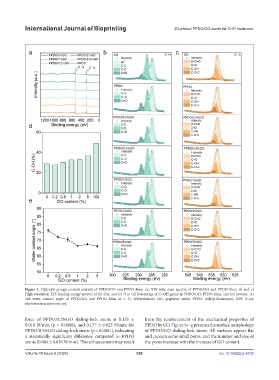

Figure 4. Hydroxyl groups content analysis of PPDO/GO and PPDO films. (a) XPS wide scan spectra of PPDO/GO and PPDO films. (b and c)

High-resolution XPS binding energy spectra of (b) C1s, and (c) O1s. (d) Percentage of C–OH group in PPDO/GO, PPDO films, and GO powder. (e)

The water contact angle of PPDO/GO and PPDO films (n = 3). Abbreviations: GO, graphene oxide; PPDO: poly(p-dioxanone); XPS, X-ray

photoelectron spectroscopy.

force of PPDO/0.2%GO sliding-lock stents is 0.155 ± from the reinforcement of the mechanical properties of

0.018 N/mm (p = 0.0008), and 0.177 ± 0.023 N/mm for PPDO by GO. Figure 5e–g presents the surface morphology

PPDO/0.5%GO sliding-lock stents (p = 0.0001), indicating of PPDO/GO sliding-lock stents. All surfaces appear flat

a statistically significant difference compared to PPDO and contain some small pores, and the number and size of

stents (0.084 ± 0.010 N/mm). This enhancement may result the pores increase with the increase of GO content.

Volume 10 Issue 6 (2024) 326 doi: 10.36922/ijb.4530