Page 106 - IJB-8-2

P. 106

3D-Printing-Assisted EADs for Preventing VUR through DJ Stents

A B

C D

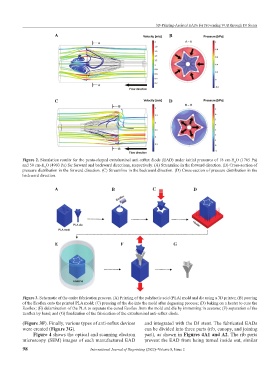

Figure 2. Simulation results for the penta-shaped extraluminal anti-reflux diode (EAD) under initial pressures of 18 cm-H O (1765 Pa)

2

and 50 cm-H O (4903 Pa) for forward and backward directions, respectively. (A) Streamline in the forward direction. (B) Cross-section of

2

pressure distribution in the forward direction. (C) Streamline in the backward direction. (D) Cross-section of pressure distribution in the

backward direction.

A B C D

E F G

Figure 3. Schematic of the entire fabrication process. (A) Printing of the polylactic acid (PLA) mold and die using a 3D printer; (B) pouring

of the Ecoflex onto the printed PLA mold; (C) pressing of the die into the mold after degassing process; (D) baking on a heater to cure the

Ecoflex; (E) delamination of the PLA to separate the cured Ecoflex from the mold and die by immersing in acetone; (F) separation of the

Ecoflex by hand; and (G) finalization of the fabrication of the extraluminal anti-reflux diode.

(Figure 3F). Finally, various types of anti-reflux devices and integrated with the DJ stent. The fabricated EADs

were created (Figure 3G). can be divided into three parts (rib, canopy, and joining

Figure 4 shows the optical and scanning electron part), as shown in Figures 4A1 and A2. The rib parts

microscopy (SEM) images of each manufactured EAD prevent the EAD from being turned inside out, similar

98 International Journal of Bioprinting (2022)–Volume 8, Issue 2