Page 122 - IJB-8-2

P. 122

Microstructured Calcium Phosphate Ceramics Scaffolds by Material Extrusion

A B

C D

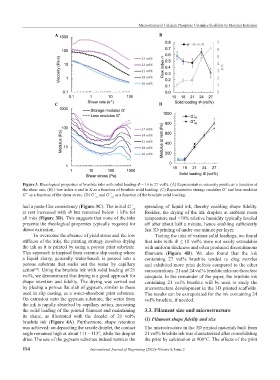

Figure 3. Rheological properties of brushite inks with solid loading Φ = 16 to 27 vol%. (A) Representative viscosity profile as a function of

the shear rate. (B) Flow index n and ln K as a function of brushite solid loading. (C) Representative storage modulus G’ and loss modulus

G” as a function of the shear stress. (D) G’ and G” as a function of the brushite solid loading.

eq

eq

had a paste-like consistency (Figure 3C). The initial G’ spreading of liquid ink, thereby enabling shape fidelity.

eq

at rest increased with Φ but remained below 1 kPa for Besides, the drying of the ink droplets at ambient room

all inks (Figure 3D). This suggests that none of the inks temperature and >70% relative humidity typically leveled

presents the rheological properties typically required for off after about half a minute, hence enabling sufficiently

direct extrusion. fast 3D printing of under one minute per layer.

To overcome the absence of yield stress and the low Testing the inks of various solid loadings, we found

stiffness of the inks, the printing strategy involves drying that inks with Φ ≤ 18 vol% were not easily extrudable

the ink as it is printed by using a porous print substrate. with uniform thickness and often produced discontinuous

This approach is inspired from ceramic slip casting where filaments (Figure 4B). We also found that the ink

a liquid slurry, generally water-based, is poured into a containing 27 vol% brushite tended to clog nozzles

porous substrate that sucks out the water by capillary and exhibited more print defects compared to the other

action . Using the brushite ink with solid loading of 21 concentrations. 21 and 24 vol% brushite inks are therefore

[35]

vol%, we demonstrated that drying is a good approach for adequate. In the remainder of the paper, the brushite ink

shape retention and fidelity. The drying was carried out containing 21 vol% brushite will be used to study the

by placing a porous flat slab of gypsum, similar to those microstructure development in the 3D printed scaffolds.

used in slip casting, as a water-absorbent print substrate. The results can be extrapolated for the ink containing 24

On extrusion onto the gypsum substrate, the water from vol% brushite, if needed.

the ink is rapidly absorbed by capillary action, increasing

the solid loading of the printed filament and maintaining 3.3. Filament size and microstructure

its shape, as illustrated with the droplet of 21 vol%

brushite ink (Figure 4A). Furthermore, shape retention (1) Filament shape fidelity and size

was achieved: on depositing the sessile droplet, the contact The microstructure in the 3D printed materials built from

angle remained high at about 111 – 113°, while the droplet 21 vol% brushite ink was characterized after consolidating

dries. The use of the gypsum substrate indeed restricts the the print by calcination at 900°C. The effects of the print

114 International Journal of Bioprinting (2022)–Volume 8, Issue 2