Page 343 - IJB-9-4

P. 343

International Journal of Bioprinting Bioprinting with machine learning

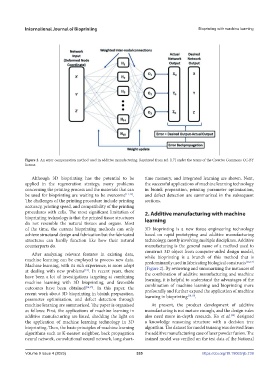

Figure 2. An error compensation method used in additive manufacturing. Reprinted from ref. [17] under the terms of the Creative Commons CC-BY

license.

Although 3D bioprinting has the potential to be time memory, and integrated learning are shown. Next,

applied in the regeneration strategy, many problems the successful applications of machine learning technology

concerning the printing process and the materials that can in bioink preparation, printing parameter optimization,

be used for bioprinting are waiting to be overcome [11,12] . and defect detection are summarized in the subsequent

The challenges of the printing procedure include printing sections.

accuracy, printing speed, and compatibility of the printing

procedures with cells. The most significant limitation of 2. Additive manufacturing with machine

bioprinting technology is that the printed tissue structures learning

do not resemble the natural tissues and organs. Most

of the time, the current bioprinting methods can only 3D bioprinting is a new tissue engineering technology

achieve structural design and fabrication but the fabricated based on rapid prototyping and additive manufacturing

structures can hardly function like how their natural technology, mostly involving multiple disciplines. Additive

counterparts do. manufacturing is the general name of a method used to

After analyzing relevant features in existing data, construct 3D object from computer-aided design model,

machine learning can be employed to process new data. while bioprinting is a branch of this method that is

[16,17]

Machine learning, with its rich experience, is more adept predominantly used in fabricating biological constructs

at dealing with new problems . In recent years, there (Figure 2). By reviewing and summarizing the instances of

[13]

have been a lot of investigations targeting at combining the combination of additive manufacturing and machine

machine learning with 3D bioprinting, and favorable learning, it is helpful to understand the advantages of the

outcomes have been obtained [14,15] . In this paper, the combination of machine learning and bioprinting more

recent work about 3D bioprinting in bioink preparation, profoundly and further expand the application of machine

[18,19]

parameter optimization, and defect detection through learning in bioprinting .

machine learning are summarized. The paper is organized At present, the product development of additive

as follows: First, the applications of machine learning in manufacturing is not mature enough, and the design rules

additive manufacturing are listed, shedding the light on also need more in-depth research. Ko et al. designed

[20]

the application of machine learning technology in 3D a knowledge reasoning structure with a decision tree

bioprinting. Then, the basic principles of machine learning algorithm. The dataset for model training was derived from

algorithms such as K-nearest neighbor, back propagation the additive manufacturing case of laser powder fusion. The

neural network, convolutional neural network, long short- trained model was verified on the test data of the National

Volume 9 Issue 4 (2023) 335 https://doi.org/10.18063/ijb.739