Page 459 - IJB-9-4

P. 459

International Journal of Bioprinting β-Ti21S auxetic FGPs produced by laser powder bed fusion

Where C , C , n and n are the Gibson-Ashby constants. When considering human bone, for example, the

2

1

2

1

Considering the strut-based lattices, particular interest is femur is characterized by variable porosity of the

paid to auxetic structures, showing a negative Poisson’s trabecular structure depending on the position within the

[31]

ratio in case of implants that are subjected to bending bone . Implants carrying FGPSs have attracted growing

stress. As an example, a femoral implant during the interest in recent years [32-37] thanks to the possibility of

normal life of the patient undergoes cyclic bending stress. tuning their porosity to adapt the implant stiffness to

This mechanical loading places one part of the prosthesis that of the surrounding bony tissue and to promote the

in cyclic tension and another in cyclic compression. The osseointegration owing to an optimal pore size in contact

use of auxetic structure in the tensioned part permits with bone (100 – 600 µm). In addition, a FGPS facilitates

to promote the compression of the interface between an adequate connection between implant’s porous and

implant and bone due to the lateral expansion linked to solid parts. The effect of the direction of the porosity

its negative Poisson’s ratio. This should avoid or mitigate gradient with respect to the direction of loading in the

[38]

the loosening of the prosthesis. In addition, a decreased compression test was evaluated by De Galarreta et al. .

Young’s modulus by decreasing Poisson’s ratio is observed In detail, the radially graded porous structure is affected by

for this class of metamaterials [23-30] . In fact, the Poisson’s all the different porosity levels through the mixture rule.

ratio and consequently the elastic modulus are influenced Differently, the elastic modulus of longitudinally graded

by the cell parameters, such as a/b aspect ratio and θ structures is dominated by the collapse of the weakest layer

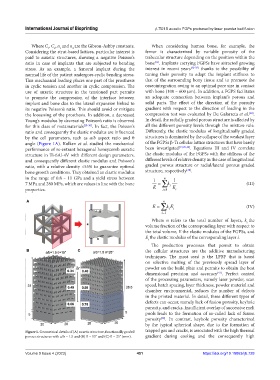

angle (Figure 1A). Kolken et al. studied the mechanical of the FGPSs β-Ti cellular lattice structures that have barely

performance of re-entrant hexagonal honeycomb auxetic been investigated [19,39,40] . Equations III and IV correlate

structure in Ti-6Al-4V with different design parameters, the elastic modulus of the FGPSs with the stiffness of the

and consequently different elastic modulus and Poisson’s different levels of relative density in the case of longitudinal

ratio, with a relative density <55% to guarantee optimal graded porous structure or radial/lateral porous graded

[38]

bone growth conditions. They obtained an elastic modulus structure, respectively .

in the range of 0.8 – 11 GPa and a yield stress between 1 n 1

7 MPa and 280 MPa, which are values in line with the bone = ∑ k i (III)

properties. E i= 1 E i

A n

E = ∑ k E i (IV)

i

i=1

Where n refers to the total number of layers, k the

i

volume fraction of the corresponding layer with respect to

the total volume, E the elastic modulus of the FGPSs, and

E the elastic modulus of the corresponding layer i.

i

The production processes that permit to obtain

B C the cellular structures are the additive manufacturing

techniques. The most used is the LPBF that is based

on selective melting of the previously spread layer of

powder on the build plate and permits to obtain the best

dimensional precision and accuracy . Perfect control

[41]

of the processing parameters, namely laser powder, scan

speed, hatch spacing, layer thickness, powder material and

chamber environmental, reduces the number of defects

in the printed material. In detail, three different types of

defects can occur, namely lack of fusion porosity, keyhole

porosity, and cracks. Insufficient overlap of successive melt

pools leads to the formation of so-called lack of fusion

porosity . In contrast, keyhole porosity characterized

[42]

by the typical spherical shape, due to the formation of

Figure 1. Geometrical details of (A) auxetic structure, functionally graded trapped gas and cracks, is associated with the high thermal

porous structures with a/b = 1.5 and (B) θ = 15° and (C) θ = 25° (mm). gradient during cooling and the consequently high

Volume 9 Issue 4 (2023) 451 https://doi.org/10.18063/ijb.728