Page 464 - IJB-9-4

P. 464

International Journal of Bioprinting β-Ti21S auxetic FGPs produced by laser powder bed fusion

A B C

D E F

G H I

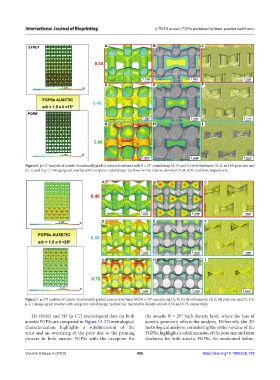

Figure 6. µ-CT analysis of auxetic functionally graded porous structures with θ = 15° considering (A, D, and G) strut thickness, (B, E, and H) pore size and

(C, F, and I) µ-CT image (grey) overlap with computer-aided design (yellow) for the relative density of 0.34, 0.49, and 0.66, respectively.

A B C

D E F

G H I

Figure 7. µ-CT analysis of auxetic functionally graded porous structures with θ = 25° considering (A, D, G) strut thickness, (B, E, H) pore size and (C, F, I)

µ-CT image (grey) overlap with computer-aided design (yellow) for the relative density of 0.40, 0.58 and 0.75, respectively.

2D (SEM) and 3D (µ-CT) metrological data on both the auxetic θ = 25° high density level, where the loss of

auxetic FGPSs are compared in Figure 12. 2D metrological auxetic geometry affects the analysis. Differently, the 3D

characterization highlights a subdimension of the metrological analysis, considering the entire volume of the

strut and an oversizing of the pore due to the printing FGPSs, highlights a subdimension of the pore size and strut

process in both auxetic FGPSs with the exception for thickness for both auxetic FGPSs. As mentioned before,

Volume 9 Issue 4 (2023) 456 https://doi.org/10.18063/ijb.728