Page 295 - IJB-9-5

P. 295

International Journal of Bioprinting Blood components for tissue graft bioprinting

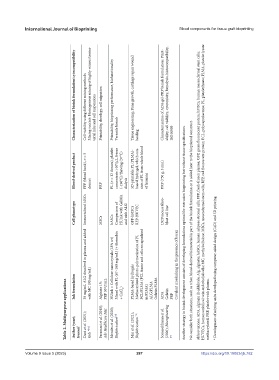

Characterization of bioink formulation/cytocompatibility

Cell viability using different mixing methods Mixing success: Homogenous mixing of highly viscous bioma- terial inks and cell suspensions Printability, rheology, cell migration Printability, bioprinting performance, biofunctionality Versatile bioink Tissue engineering: Bone growth, cartilage repair wound healing Characterization of ADA-gel-PRP bioink formulation: Print- ability, cell viability, cytotoxicity, hemolysis, histocompa

Blood-derived product FFP (blood bank), n = 5 donors PRP PL (n = 12 donors), platelet concentrate >10 6 /µL, freeze (-196°C)/thawing (37°C) dialysis 3D-printable PL (PLMA)- based hydrogel, which con- sists of PL from whole blood of humans PRP (750 g, 5 min) HUVECs, human umbilical vein endothelial cells; MC, methylcellulose; MSCs, mesenchymal stem cells; RFP, red fluorescent protein; PCL, polycaprolactone; PL, platelet lysa

Cell phenotype Immortalized MSCs MSCs hASCs Comparison of HUink with GelMA and with ALG GFP-hMSCs RFP-HUVEC L929 mouse fibro- blast cell line Another strategy in bioink development consists of developing formulations optimal for extrusion bioprinting but without tissue specifications. We consider both situations, such as when blood-derived biomaterial is part of the bioink formulation or is added later to the bioprinted constru

30 mg/mL ALG dissolved in plasma and added with MC (90 mg/mL) HUink = Cellulose nanocrystals (18% wt) Mixed with PL (67–160 mg/mL) (+ thrombin PLMA-based hydrogels Methacrylated photo-polymerization of PL PCL/PLMA (PCL frame and cells encapsulated Covalent crosslinking in the presence of borax * Development of mixing units developed using computer-aided design (CAD) and 3D printing.

Table 2. Multipurpose applications Ink formulation Author (year); Dani et al. (2021); Alginate 1% Faramazi et al. (2018); PRP 50 U/mL Adv Healthcare Mat Mendes et al. (2020); Biofabrication [73] + CaCl 2 ) Min et al. (2021); Biofabrication [74] in PLMA) ALG:PLMA Gelatin:PLMA ADA Somasekharan et al. Gelatin (2020); Bioengineering PRP methacrylated; PRP, platelet-rich plasma.

Volume 9 Issue 5 (2023) Journal Gels * [72] 287 [75] https://doi.org/10.18063/ijb.762