Page 181 - v11i4

P. 181

International Journal of Bioprinting Design of SLM-Ta artificial vertebral body

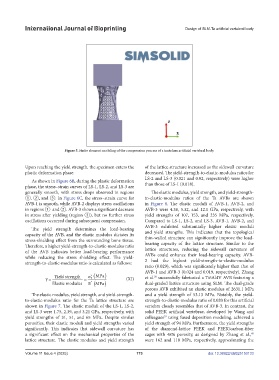

Figure 5. Finite element modeling of the compression process of a tantalum artificial vertebral body.

Upon reaching the yield strength, the specimen enters the of the lattice structure increased as the sidewall curvature

plastic deformation phase. decreased. The yield-strength-to-elastic-modulus ratios for

LS-2 and LS-3 (0.021 and 0.02, respectively) were higher

As shown in Figure 6B, during the plastic deformation

phase, the stress–strain curves of LS-1, LS-2, and LS-3 are than those of LS-1 (0.018).

generally smooth, with stress drops observed in regions The elastic modulus, yield strength, and yield-strength-

①, ②, and ③. In Figure 6C, the stress–strain curve for to-elastic-modulus ratios of the Ta AVBs are shown

AVB-1 is smooth, while AVB-2 displays stress oscillations in Figure 8. The elastic moduli of AVB-1, AVB-2, and

in regions ① and ②. AVB-3 shows a significant decrease AVB-3 were 4.38, 5.32, and 12.1 GPa, respectively, with

in stress after yielding (region ③), but no further stress yield strengths of 107, 153, and 235 MPa, respectively.

oscillations occurred during subsequent compression. Compared to LS-1, LS-2, and LS-3, AVB-1, AVB-2, and

AVB-3 exhibited substantially higher elastic moduli

The yield strength determines the load-bearing

capacity of the AVB, and the elastic modulus dictates its and yield strengths. This indicates that the topological

stress-shielding effect from the surrounding bone tissue. thin-walled structure can significantly improve the load-

Therefore, a higher yield-strength-to-elastic-modulus ratio bearing capacity of the lattice structure. Similar to the

of the AVB indicates better load-bearing performance lattice structures, reducing the sidewall curvature of

while reducing the stress shielding effect. The yield- AVBs could enhance their load-bearing capacity. AVB-

strength-to-elastic-modulus ratio is calculated as follows: 2 had the highest yield-strength-to-elastic-modulus

ratio (0.029), which was significantly higher than that of

AVB-1 and AVB-3 (0.024 and 0.019, respectively). Zhang

58

γ Yield strength y σ * MPa (XI) et al. successfully fabricated a Ti6Al4V AVB featuring a

Elastic modulus E * MPa dual-graded lattice structure using SLM. The dual-grade

porous AVB exhibited an elastic modulus of 2631.1 MPa

The elastic modulus, yield strength, and yield-strength- and a yield strength of 53.13 MPa. Notably, the yield-

to-elastic-modulus ratio for the Ta lattice structure are strength-to-elastic-modulus ratio of 0.020 for this artificial

shown in Figure 7. The elastic moduli of the LS-1, LS-2, vertebra closely resembles that of AVB-3. In contrast, the

and LS-3 were 1.75, 2.39, and 3.21 GPa, respectively, with solid PEEK artificial vertebrae, developed by Wang and

yield strengths of 31, 51, and 65 MPa. Despite similar colleagues using fused deposition modeling, achieved a

59

porosities, their elastic moduli and yield strengths varied yield strength of 94 MPa. Furthermore, the yield strengths

significantly. This indicates that sidewall curvature has of the diamond-lattice PEEK and PEEK/carbon-fiber

a significant effect on the mechanical properties of the cages with 48% porosity, as designed by Zhang et al.,

60

lattice structure. The elastic modulus and yield strength were 162 and 118 MPa, respectively, approximating the

Volume 11 Issue 4 (2025) 173 doi: 10.36922/IJB025150133