Page 20 - v11i4

P. 20

International Journal of Bioprinting 3D-printed scaffolds for osteochondral defect

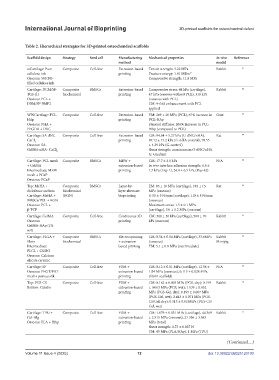

Table 2. Hierarchical strategies for 3D-printed osteochondral scaffolds

Scaffold design Strategy Seed cell Manufacturing Mechanical properties In vivo Reference

method model

wCartilage: Pure Composite Cell-free Extrusion-based Tensile strength: 5.22 MPa Rabbit 41

cellulose ink printing Fracture energy: 1.81 MJ/m³

Osseous: 58S BG- Compressive strength: 11.8 MPa

filled cellulose ink

Cartilage: DCM/SF- Composite BMSCs Extrusion-based Compressive stress: 44 kPa (cartilage), Rabbit 42

TGF-β1 biochemical printing 47 kPa (osseous without PCL), 310 kPa

Osseous: PCL + (osseous with PCL)

DBM/SF-BMP2 CM: 9-fold enhancement with PCL

applied

WWCartilage: PCL- Composite Cell-free Extrusion-based YM: 269 ± 20 MPa (PCL), 67% increase in Goat 43

HAp printing PCL-HAp

Osseous: PHA + Flexural stiffness: 206% increase in PCL-

PEGDA + DVC HAp (compared to PCL)

Cartilage: SA-dNC- Composite Cell-free Extrusion-based CM: 94.64 ± 5.27 kPa (G-dNC/nHA), Rat 44

CaCl 2 printing 89.12 ± 15.2 kPa (G-nHA control), 70.55

Osseous: SA- ± 4.29 kPa (G-control)

GelMA-nHA- CaCl Shear strength: maximum in G-dNC/nHA

2

G: Gradient

Cartilage: PCL mesh Composite BMSCs MEW + CM: 17.7 ± 2.0 kPa N/A 45

+ GelMA extrusion-based In vivo interface adhesion strength: 6.6 ±

Intermediate: MEW printing 1.7 kPa (Day 1), 24.4 ± 6.5 kPa (Day 42)

mesh + PCaP

Osseous: PCaP

Top: MeHA + Composite BMSCs Layer-by- EM: 85 ± 10 MPa (cartilage), 185 ± 15 Rat 46

diclofenac sodium biochemical layer alternate MPa (osseous)

Cartilage: MeHA + (KGN) bioprinting S: 55 ± 5 N/mm (cartilage), 110 ± 8 N/mm

BMSCs/PCL + KGN (osseous)

Osseous: PCL + Maximum stress: 1.5 ± 0.1 MPa

β-TCP (cartilage), 3.0 ± 0.2 MPa (osseous)

Cartilage: GelMA Composite Cell-free Continuous 3D CM: 300 ± 50 kPa (cartilage), 500 ± 70 Rabbit 47

Osseous: printing kPa (osseous)

GelMA-HAp (1%

w/t)

Cartilage: PLGA + Composite BMSCs Electrospinning CM: 0.54 ± 0.04 MPa (cartilage), 33.6MPa Rabbit 48

fibrin biochemical + extrusion- (osseous) Minipig

Intermediate: based printing YM: 5.1 ± 0.8 MPa (intermediate)

PLCL + CS/BG

Osseous: Calcium

silicate ceramic

Cartilage: SF Composite Cell-free FDM + CM: 0.12 ± 0.01 MPa (cartilage), 12.56 ± N/A 49

Osseous: PEGT/PBT extrusion-based 1.94 MPa (osseous), 0.113 ± 0.028 MPa

mesh+ porous silk printing (fibrin scaffold)

Top: PGS-CS Composite Cell-free FDM + CM: 0.162 ± 0.005 MPa (PGS, dry); 0.159 Rabbit 50

Bottom: Gelatin extrusion-based ± 0.003 MPa (PGS, wet); 1.139 ± 0.052

printing MPa (PGS-Gel, dry); 0.195 ± 0.007 MPa

(PGS-Gel, wet); 2.443 ± 0.071 MPa (PGS-

CS/Gel, dry); 0.315 ± 0.019MPa (PGS-CS/

Gel, wet)

Cartilage: TPU + Composite Cell-free FDM + CM: 1.079 ± 0.031 MPa (cartilage), 44.369 Rabbit 51

Gel-Alg extrusion-based ± 2.515 MPa (osseous), 21.336 ± 3.683

Osseous: PLA + HAp printing MPa (total)

Shear strength: 0.73 ± 0.027 N

YM: 45 MPa (PLA/HAp), 1 MPa (TPU)

(Continued....)

Volume 11 Issue 4 (2025) 12 doi: 10.36922/IJB025120100