Page 238 - v11i4

P. 238

International Journal of Bioprinting Fine collagen scaffold for osteogenesis

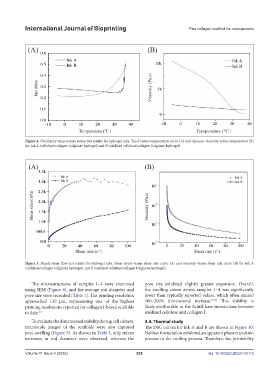

Figure 4. Oscillatory temperature sweep test results for hydrogel inks. Tan δ versus temperature curve (A) and dynamic viscosity versus temperature (B)

for ink A (cellulose/collagen I/alginate hydrogel) and B (oxidized cellulose/collagen I/alginate hydrogel).

Figure 5. Steady shear flow test results for hydrogel inks. Shear stress versus shear rate curve (A) and viscosity versus shear rate curve (B) for ink A

(cellulose/collagen I/alginate hydrogel) and B (oxidized cellulose/collagen I/alginate hydrogel).

The microstructures of samples 1–4 were examined pore size exhibited slightly greater expansion. Overall,

using SEM (Figure 8), and the average rod diameter and the swelling extent across samples 1–4 was significantly

pore size were recorded (Table 1). The printing resolution lower than typically reported values, which often exceed

approached 150 μm, representing one of the highest 100–200% dimensional increase. 34,35 This stability is

printing resolutions reported for collagen I-based scaffolds likely attributable to the Schiff-base interactions between

to date. 33 oxidized cellulose and collagen I.

To evaluate the dimensional stability during cell culture, 3.4. Thermal study

microscale images of the scaffolds were also captured The DSC curves for ink A and B are shown in Figure 10.

post-swelling (Figure 9). As shown in Table 1, only minor Neither formulation exhibited an apparent phase transition

increases in rod diameter were observed, whereas the process in the cooling process. Therefore, the printability

Volume 11 Issue 4 (2025) 230 doi: 10.36922/IJB025140116