Page 81 - MSAM-2-4

P. 81

Materials Science in Additive Manufacturing Laser DED-produced Ti-6Mn-4Mo alloy

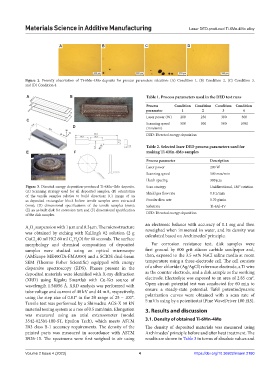

A B C D

Figure 2. Porosity observation of Ti-6Mn-4Mo deposits for process parameters selection: (A) Condition 1, (B) Condition 2, (C) Condition 3,

and (D) Condition 4.

A B Table 1. Process parameters used in the DED test runs

Process Condition Condition Condition Condition

parameter 1 2 3 4

Laser power (W) 200 250 300 300

C

D Scanning speed 500 500 500 1000

(mm/min)

DED: Directed energy deposition

Table 2. Selected laser DED process parameters used for

E F making Ti‑6Mn‑4Mo samples

Process parameter Description

Laser power 200 W

Scanning speed 500 mm/min

Hatch spacing 300 μm

Figure 3. Directed energy deposition-produced Ti-6Mn-4Mo deposits. Scan strategy Unidirectional, 180° rotation

(A) Scanning strategy used for all deposited samples; (B) orientation Shield gas flow rate 0.8 L/min

of the tensile samples relative to build direction; (C) image of an

as-deposited rectangular block before tensile samples were extracted Powder flow rate 0.70 g/min

(mm); (D) dimensional specifications of the tensile samples (mm); Substrate Ti-6Al-4V

(E) an as-built disk for corrosion test; and (F) dimensional specification

of the disk samples. DED: Directed energy deposition

an electronic balance with accuracy of 0.1 mg and then

A O suspension with 1 μm and 0.3 μm. The microstructure reweighed when immersed in water, and its density was

3

2

was obtained by etching with Kalling’s #2 solution (2 g calculated based on Archimedes’ principle.

CuCl 40 ml HCl 60 ml C H O) for 60 seconds. The surface

2

6

2

morphology and chemical composition of deposited For corrosion resistance test, disk samples were

samples were studied using an optical microscope first ground by 600 grit silicon carbide sandpaper and,

(AMScope ME400TA-FMA050) and a SCIOS dual-beam then, exposed to the 3.5 wt% NaCl saline media at room

SEM (Thermo Fisher Scientific) equipped with energy temperature using a three-electrode cell. The cell consists

dispersive spectroscopy (EDS). Phases present in the of a silver chloride (Ag/AgCl) reference electrode, a Ti wire

deposited materials were identified with X-ray diffraction as the counter electrode, and a disk sample as the working

2

(XRD) using Rigaku Smartlab with Cu-Kα source of electrode. Electrolyte was exposed to an area of 2.85 cm .

wavelength 1.54056 Å. XRD analysis was performed with Open circuit potential test was conducted for 60 min to

tube voltage and current of 40 kV and 44 mA, respectively, ensure a steady-state potential. Tafel potentiodynamic

using the step size of 0.01° in the 2θ range of 25 – 100°. polarization curves were obtained with a scan rate of

Tensile test was performed by a Shimadzu AGS-X 50 kN 5 mV/s using by a potentiostat (Pine WaveDriver 100 EIS).

material testing system at a rate of 0.5 mm/min. Elongation 3. Results and discussion

was measured using an axial extensometer (model

3542-025M-100-ST, Epsilon Tech), which meets ASTM 3.1. Density of obtained Ti-6Mn-4Mo

E83 class B-1 accuracy requirements. The density of the The density of deposited materials was measured using

printed parts was measured in accordance with ASTM Archimedes’ principle before and after heat treatment. The

B926-15. The specimens were first weighed in air using results are shown in Table 3 in terms of absolute values and

Volume 2 Issue 4 (2023) 4 https://doi.org/10.36922/msam.2180