Page 47 - MSAM-3-1

P. 47

Materials Science in Additive Manufacturing Adhesion study for multi-material 3D printing

tissue engineering, and aerospace and defense. to conduct electricity, and TPU for its elasticity and

1-5

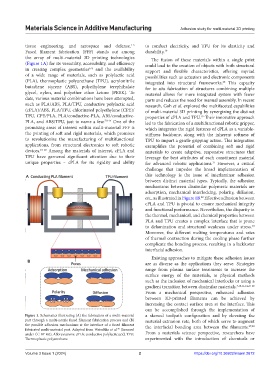

Fused filament fabrication (FFF) stands out among durability. 19

the array of multi-material 3D printing technologies The fusion of these materials within a single print

(Figure 1A) for its versatility, accessibility, and efficiency could lead to the creation of objects with both structural

in creating complex geometries and the availability support and flexible characteristics, offering myriad

6-8

of a wide range of materials, such as polylactic acid possibilities such as actuators and electronic components

(PLA), thermoplastic polyurethane (TPU), acrylonitrile integrated into structural frameworks. This capacity

20

butadiene styrene (ABS), polyethylene terephthalate for in situ fabrication of structures combining multiple

glycol, nylon, and polyether ether ketone (PEEK). To material allows for more integrated system with fewer

date, various material combinations have been attempted, parts and reduces the need for manual assembly. In recent

such as PLA/ABS, PLA/TPU, conductive polylactic acid research, Goh et al. explored the multifaceted capabilities

(cPLA)/ABS, PLA/TPU, chlorinated polyethylene (CPE)/ of multi-material 3D printing by synergizing the distinct

TPU, CPE/PLA, PLA/conductive-PLA, ABS/conductive- properties of cPLA and TPU. Their innovative approach

19

PLA, and ABS/TPU, just to name a few. 7,9-14 One of the led to the fabrication of a multifunctional robotic gripper,

promising areas of interest within multi-material FFF is which integrates the rigid features of cPLA as a variable-

the printing of soft and rigid materials, which promises stiffness backbone, along with the inherent softness of

to revolutionize the manufacturing of multifunctional TPU to impart a gentle gripping action. This integration

applications, from structural electronics to soft robotic exemplifies the potential of combining soft and rigid

devices. 15-18 Among the materials of interest, cPLA and materials to create adaptive, responsive structures that

TPU have garnered significant attention due to their leverage the best attributes of each constituent material

unique properties – cPLA for its rigidity and ability for advanced robotic applications. However, a critical

21

challenge that impedes the broad implementation of

A this technology is the issue of interlaminar adhesion

between distinct material types. Typically, the adhesion

mechanisms between dissimilar polymeric materials are

adsorption, mechanical interlocking, polarity, diffusion,

etc., as illustrated in Figure 1B. Effective adhesion between

22

cPLA and TPU is pivotal to ensure mechanical integrity

and functional performance. Nevertheless, the disparity in

the thermal, mechanical, and chemical properties between

PLA and TPU creates a complex interface that is prone

to delamination and structural weakness under stress.

18

Moreover, the different melting temperatures and rates

of thermal contraction during the cooling phase further

complicate the bonding process, resulting in a lackluster

interfacial adhesion.

Existing approaches to mitigate these adhesion issues

B

are as diverse as the applications they serve. Strategies

range from plasma surface treatments to increase the

surface energy of the materials, to physical methods

such as the inclusion of mechanical interlocks or using a

gradient transition between dissimilar materials. 7,10,11,14,23-26

From a mechanical perspective, enhanced adhesion

between 3D-printed filaments can be achieved by

increasing the contact surface area at the interface. This

can be accomplished through the implementation of

Figure 1. Schematics illustrating (A) the fabrication of a multi-material a skewed toolpath configuration and by elevating the

part through a multi-nozzle fused filament fabrication process and (B) material extrusion rate, both of which serve to augment

the possible adhesion mechanisms at the interface of a fused filament the interfacial bonding area between the filaments. 27,28

fabricated multi-material part. Adapted from Watschke et al. (licensed

36

under CC BY 4.0). Abbreviations: cPLA: conductive polylactic acid; TPU: From a materials science perspective, researchers have

Thermoplastic polyurethane. experimented with the introduction of chemicals or

Volume 3 Issue 1 (2024) 2 https://doi.org/10.36922/msam.2672