Page 13 - AJWEP-22-4

P. 13

IoT-based water quality monitoring

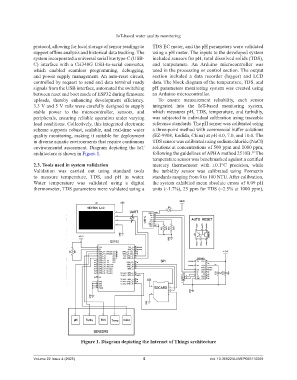

protocol, allowing for local storage of sensor readings to TDS EC meter, and the pH parameters were validated

support offline analysis and historical data tracking. The using a pH meter. The inputs to the developed system

system incorporated a universal serial bus type-C (USB- included sensors for pH, total dissolved solids (TDS),

C) interface with a CH340G USB-to-serial converter, and temperature. An Arduino microcontroller was

which enabled seamless programming, debugging, used in the processing or control section. The output

and power supply management. An auto-reset circuit, section included a data recorder (logger) and LCD

controlled by request to send and data terminal ready data. The block diagram of the temperature, TDS, and

signals from the USB interface, automated the switching pH parameters monitoring system was created using

between reset and boot mode of ESP32 during firmware an Arduino microcontroller.

uploads, thereby enhancing development efficiency. To ensure measurement reliability, each sensor

3.3 V and 5 V rails were carefully designed to supply integrated into the IoT-based monitoring system,

stable power to the microcontroller, sensors, and which measures pH, TDS, temperature, and turbidity,

peripherals, ensuring reliable operation under varying was subjected to individual calibration using traceable

load conditions. Collectively, this integrated electronic reference standards. The pH sensor was calibrated using

scheme supports robust, scalable, and real-time water a three-point method with commercial buffer solutions

quality monitoring, making it suitable for deployment (EZ-9908, Kedida, China) at pH 4.0, 7.0, and 10.0. The

in diverse aquatic environments that require continuous TDS sensor was calibrated using sodium chloride (NaCl)

environmental assessment. Diagram depicting the IoT solutions at concentrations of 500 ppm and 1000 ppm,

39

architecture is shown in Figure 1. following the guidelines of APHA method 2510B. The

temperature sensor was benchmarked against a certified

2.3. Tools used in system validation mercury thermometer with ±0.1°C precision, while

Validation was carried out using standard tools the turbidity sensor was calibrated using Formazin

to measure temperature, TDS, and pH in water. standards ranging from 0 to 100 NTU. After calibration,

Water temperature was validated using a digital the system exhibited mean absolute errors of 0.09 pH

thermometer, TDS parameters were validated using a units (~1.7%), 25 ppm for TDS (~2.5% at 1000 ppm),

Figure 1. Diagram depicting the Internet of Things architecture

Volume 22 Issue 4 (2025) 5 doi: 10.36922/AJWEP025110069