Page 41 - ESAM-1-4

P. 41

Engineering Science in

Additive Manufacturing Machine learning for biomedical metal AM

A

B

C

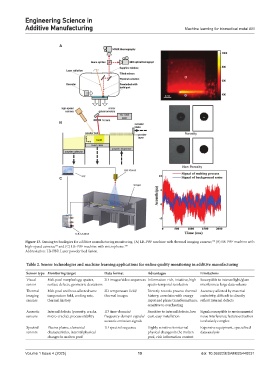

Figure 13. Sensing technologies for additive manufacturing monitoring. (A) LB-PBF machine with thermal imaging camera; (B) LB-PBF machine with

128

high-speed camera; and (C) LB-PBF machine with microphone. 138

132

Abbreviation: LB-PBF: Laser powder bed fusion.

Table 2. Sensor technologies and machine learning applications for online quality monitoring in additive manufacturing

Sensor type Monitoring target Data format Advantages Limitations

Visual Melt pool morphology, spatter, 2D images/video sequences Information-rich, intuitive, high Susceptible to intense light/glare

sensor surface defects, geometric deviations spatio-temporal resolution interference; large data volume

Thermal Melt pool and heat-affected zone 2D temperature field/ Directly records process thermal Accuracy affected by material

imaging temperature field, cooling rate, thermal images history; correlates with energy emissivity; difficult to directly

sensors thermal history input and phase transformations; reflect internal defects

sensitive to overheating

Acoustic Internal defects (porosity, cracks, 1D time-domain/ Sensitive to internal defects, low Signals susceptible to environmental

sensors micro-cracks), process stability frequency-domain signals/ cost, easy installation noise interference; feature extraction

acoustic emission signals is relatively complex

Spectral Plasma plume, elemental 1D spectral sequence Highly sensitive to internal Expensive equipment, specialized

sensors characteristics, internal physical physical changes in the molten data analysis

changes in molten pool pool; rich information content

Volume 1 Issue 4 (2025) 19 doi: 10.36922/ESAM025440031