Page 89 - IJAMD-1-3

P. 89

International Journal of AI for

Materials and Design

Review of gas turbine blade failures by erosion

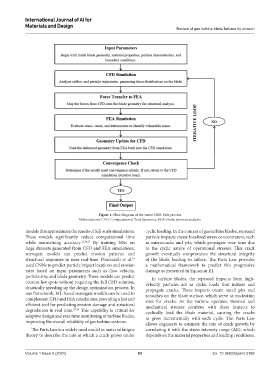

Figure 1. Flow diagram of the entire CFD-FEA process

Abbreviations: CFD: Computational fluid dynamics; FEA: Finite element analysis.

models that approximate the results of full-scale simulations. cyclic loading. In the context of gas turbine blades, repeated

These models significantly reduce computational time particle impacts create localized stress concentrators, such

while maintaining accuracy. 33,34,37 By training NNs on as microcracks and pits, which propagate over time due

large datasets generated from CFD and FEA simulations, to the cyclic nature of operational stresses. This crack

surrogate models can predict erosion patterns and growth eventually compromises the structural integrity

structural responses in near real-time. Poursaeidi et al. of the blade, leading to failure. The Paris Law provides

61

used CNNs to predict particle impact locations and erosion a mathematical framework to predict this progressive

rates based on input parameters such as flow velocity, damage as presented in Equation III.

particle size, and blade geometry. These models can predict In turbine blades, the repeated impacts from high-

erosion hot spots without requiring the full CFD solution, velocity particles act as cyclic loads that initiate and

drastically speeding up the design optimization process. In propagate cracks. These impacts create small pits and

our framework, ML-based surrogate models can be used to scratches on the blade surface, which serve as nucleation

complement CFD and FEA simulations, providing a fast and sites for cracks. As the turbine operates, thermal and

efficient tool for predicting erosion damage and structural mechanical stresses combine with these impacts to

degradation in real time. 55,56 This capability is critical for cyclically load the blade material, causing the cracks

adaptive design and real-time monitoring of turbine blades, to grow incrementally with each cycle. The Paris Law

improving the overall reliability of gas turbine systems. allows engineers to estimate the rate of crack growth by

The Paris Law is a widely used model in material fatigue correlating it with the stress intensity range (ΔK), which

theory to describe the rate at which a crack grows under depends on the material properties and loading conditions.

Volume 1 Issue 3 (2024) 83 doi: 10.36922/ijamd.5188