Page 55 - IJB-1-1

P. 55

Edgar Y. S. Tan and Wai Yee Yeong

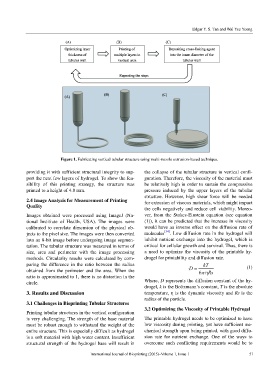

Figure 1. Fabricating vertical tubular structure using multi-nozzle extrusion-based technique.

providing it with sufficient structural integrity to sup- the collapse of the tubular structure in vertical confi-

port the next few layers of hydrogel. To show the fea- guration. Therefore, the viscosity of the material must

sibility of this printing strategy, the structure was be relatively high in order to sustain the compressive

printed to a height of 4.8 mm. pressure induced by the upper layers of the tubular

structure. However, high shear force will be needed

2.4 Image Analysis for Measurement of Printing for extrusion of viscous materials, which might impact

Quality

the cells negatively and reduce cell viability. Moreo-

Images obtained were processed using ImageJ (Na- ver, from the Stokes-Einstein equation (see equation

tional Institiute of Health, USA). The images were (1)), it can be predicted that the increase in viscosity

calibrated to correlate dimension of the physical ob- would have an inverse effect on the diffusion rate of

jects to the pixel size. The images were then converted molecules [34] . Low diffusion rate in the hydrogel will

into an 8-bit image before undergoing image segmen- inhibit nutrient exchange into the hydrogel, which is

tation. The tubular structure was measured in terms of critical for cellular growth and survival. Thus, there is

size, area and perimeter with the image processing a need to optimize the viscosity of the printable hy-

methods. Circularity results were calculated by com- drogel for printability and diffusion rate.

paring the difference in the ratio between the radius (1)

obtained from the perimeter and the area. When the

ratio is approximated to 1, there is no distortion in the

circle. Where, D represents the diffusion constant of the hy-

drogel, k is the Boltzmann’s constant, T is the absolute

3. Results and Discussion temperature, η is the dynamic viscosity and Rs is the

radius of the particle.

3.1 Challenges in Bioprinting Tubular Structures

3.2 Optimizing the Viscosity of Printable Hydrogel

Printing tubular structures in the vertical configuration

is very challenging. The strength of the base material The printable hydrogel needs to be optimized to have

must be robust enough to withstand the weight of the low viscosity during printing, yet have sufficient me-

entire structure. This is especially difficult as hydrogel chanical strength upon being printed, with good diffu-

is a soft material with high water content. Insufficient sion rate for nutrient exchange. One of the ways to

structural strength of the hydrogel base will result in overcome such conflicting requirements would be to

International Journal of Bioprinting (2015)–Volume 1, Issue 1 51