Page 72 - IJB-1-1

P. 72

A novel bioactive PEEK/HA composite with controlled 3D interconnected HA network

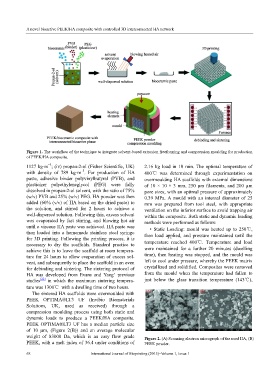

Figure 1. The workflow of the technique to integrate solvent-based extrusion freeforming and compression moulding for production

of PEEK/HA composite.

–3

1127 kg·m ; (iv) propan-2-ol (Fisher Scientific, UK) 2.16 kg load in 10 min. The optimal temperature of

–3

with density of 789 kg·m . For production of HA 400℃ was determined through experimentation on

paste, adhesive binder polyvinylbutyral (PVB), and overmoulding HA scaffolds with external dimensions

plasticizer polyethyleneglycol (PEG) were fully of 10 × 10 × 3 mm, 250 µm filaments, and 200 µm

dissolved in propan-2-ol solvent, with the ratio of 75% pore sizes, with an optimal pressure of approximately

(w/v) PVB and 25% (w/v) PEG. HA powder was then 0.39 MPa. A mould with an internal diameter of 25

added (60% (v/v) of HA based on the dried paste) to mm was prepared from tool steel, with appropriate

the solution, and stirred for 2 hours to achieve a ventilation on the inferior surface to avoid trapping air

well-dispersed solution. Following this, excess solvent within the composite. Both static and dynamic loading

was evaporated by fast stirring, and blowing hot air methods were performed as follows:

until a viscous HA paste was achieved. HA paste was • Static Loading: mould was heated up to 250℃,

then loaded into a homemade stainless steel syringe then load applied, and pressure maintained until the

for 3D printing. Following the printing process, it is

necessary to dry the scaffolds. Standard practice to temperature reached 400℃. Temperature and load

achieve this is to leave the scaffold at room tempera- were maintained for a further 20 minutes (dwelling

ture for 24 hours to allow evaporation of excess sol- time), then heating was stopped, and the mould was

vent, and subsequently to place the scaffold in an oven left to cool under pressure, whereby the PEEK matrix

for debinding and sintering. The sintering protocol of crystallized and solidified. Composites were removed

HA was developed from Evans and Yang’ previous from the mould when the temperature had fallen to

studies [22] in which the maximum sintering tempera- just below the glass transition temperature (143℃),

ture was 1300℃ with a dwelling time of two hours.

The sintered HA scaffolds were overmoulded with

PEEK OPTIMA®LT3 UF (Invibio Biomaterials

Solutions, UK, used as received) through a

compression moulding process using both static and

dynamic loads to produce a PEEK/HA composite.

PEEK OPTIMA®LT3 UF has a median particle size

of 10 µm, (Figure 2(B)) and an average molecular

weight of 83000 Da, which is an easy flow grade Figure 2. (A) Scanning electron micrograph of the used HA, (B)

PEEK, with a melt index of 36.4 under conditions of PEEK powder.

68 International Journal of Bioprinting (2015)–Volume 1, Issue 1