Page 71 - IJB-3-1

P. 71

Swee Leong Sing, Shuai Wang, Shweta Agarwala, et al.

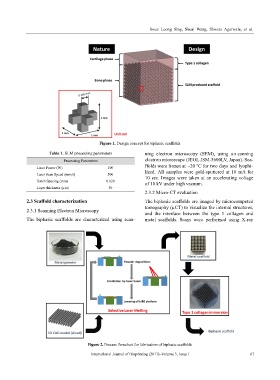

Figure 1. Design concept for biphasic scaffolds

Table 1. SLM processing parameters ning electron microscopy (SEM), using a s canning

Processing Parameters electron microscope (JEOL JSM-5600LV, Japan). Sca-

ffolds were frozen at −20 °C for two days and lyophi-

Laser Power (W) 100

Laser Scan Speed (mm/s) 500 lized. All samples were gold-sputtered at 18 mA for

10 sec. Images were taken at an accelerating voltage

Hatch Spacing (mm) 0.120

of 10 kV under high vacuum.

Layer thickness (µm) 30

2.3.2 Micro-CT evaluation

2.3 Scaffold characterization The biphasic scaffolds are imaged by microcomputed

tomography (µCT) to visualize the internal structures,

2.3.1 Scanning Electron Microscopy

and the interface between the type 1 collagen and

The biphasic scaffolds are characterized using scan- metal scaffolds. Scans were performed using X-ray

Figure 2. Process flowchart for fabrication of biphasic scaffolds

International Journal of Bioprinting (2017)–Volume 3, Issue 1 67