Page 9 - IJB-4-2

P. 9

Lee J M, et al.

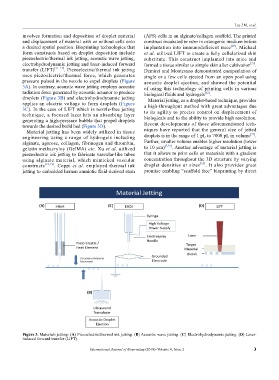

involves formation and deposition of droplet material (AFS) cells in an alginate/collagen scaffold. The printed

and displacement of material with or without cells onto construct incubated in vitro in osteogenic medium before

a desired spatial position. Bioprinting technologies that implantation into immunodeficient mice [20] . Michael

form constructs based on droplet deposition include et al. utilized LIFT to create a fully cellularized skin

piezoelectric/thermal ink jetting, acoustic wave jetting, substitute. This construct implanted into mice and

electrohydrodynamic jetting and laser-induced forward formed a tissue similar to simple skin after cultivation .

[21]

transfer (LIFT) [11–17] . Piezoelectric/thermal ink jetting Demirci and Montesano demonstrated encapsulation of

uses piezoelectric/thermal force, which generates single or a few cells ejected from an open pool using

pressure pulsed in the nozzle to expel droplets (Figure acoustic droplet ejection, and showed the potential

3A). In contrary, acoustic wave jetting employs acoustic of using this technology of printing cells in various

radiation force generated by acoustic actuator to produce biological fluids and hydrogels .

[22]

droplets (Figure 3B) and electrohydrodynamic jetting Material jetting, as a droplet-based technique, provides

applies an electric voltage to form droplets (Figure a high-throughput method with great advantages due

3C). In the case of LIFT which is nozzle-free jetting to its agility to precise control on displacement of

technique, a focused laser hits an absorbing layer biologicals and to the ability to provide high resolution.

generating a high-pressure bubble that propel droplets

towards the desired build bed (Figure 3D). Recent developments of those aforementioned tech-

Material jetting has been widely utilized in tissue niques have reported that the general size of jetted

[23]

engineering using a range of hydrogels including droplets is in the range of 1 pL to 7000 pL in volume .

alginate, agarose, collagen, fibrinogen and thrombin, Further, smaller volume enables higher resolution (lower

[7,24]

gelatin methacryloy (GelMA) etc. Xu et al. utilized to 10 µm) . Another advantage of material jetting is

piezoelectric ink jetting to fabricate vascular-like tubes that it allows to print cells or materials with a gradient

using alginate material, which mimicked vascular concentration throughout the 3D structure by varying

constructs [18,19] . Coppi et al. employed thermal ink droplet densities or sizes [25] . It also provides great

jetting to embedded human amniotic fluid-derived stem promise enabling “scaffold free” bioprinting by direct

Figure 3. Materials jetting: (A) Piezoelectric/thermal ink jetting. (B) Acoustic wave jetting. (C) Electrohydrodynamic jetting. (D) Laser-

induced forward transfer (LIFT).

International Journal of Bioprinting (2018)–Volume 4, Issue 2 3