Page 197 - IJB-10-4

P. 197

International Journal of Bioprinting Horsetail-inspired lattice for bone use

feature for mechanical performance tuning has not been mechanical performance tuning to match elastic moduli

widely studied. of bones through geometrical parameter changes. The

Hence, in this work, we propose the novel use of a matching of elastic moduli for different bones alleviates

BCC lattice with subtractive modifications on the strut the effects of stress shielding in bone scaffold-related

members to create a horsetail-inspired cross-section. The applications. Through our investigation, we also discovered

cross-section applied to the BCC lattice results in effective that the isotropy characteristic is decoupled from the outer

surface area increase and creation of flow channels. radius of the BCC; this avoids convolution that would

Additionally, we also limited the volumetric fraction, φ, otherwise increase design difficulties.

to approximately 40% to allow sufficient porosity as well 2. Materials and methods

as allow a lightweight design to mimic that of the bone.

The presence of the features allows vascular ingrowth, and 2.1. Design principles

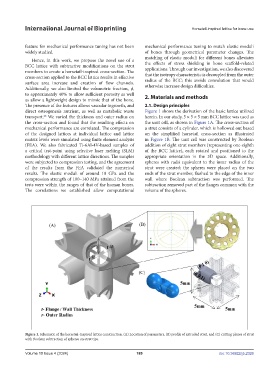

direct osteogenesis nutrient, as well as metabolic waste Figure 1 shows the derivation of the basic lattice utilized

28

transport. We varied the thickness and outer radius on herein. In our study, 5 × 5 × 5 mm BCC lattice was used as

the cross-section and found that the resulting effects on the unit cell, as shown in Figure 1A. The cross-section of

mechanical performance are correlated. The compression a strut consists of a cylinder, which is hollowed out based

of the designed lattices at individual lattice and lattice on the simplified horsetail cross-section as illustrated

matrix levels were simulated using finite element analysis in Figure 1B. The unit cell was constructed by Boolean

(FEA). We also fabricated Ti-6Al-4V-based samples of addition of eight strut members (representing one-eighth

a critical test-point using selective laser melting (SLM) of the BCC lattice), each rotated and positioned to the

methodology with different lattice directions. The samples appropriate orientation in the 3D space. Additionally,

were subjected to compression testing, and the agreement spheres with radii equivalent to the inner radius of the

of the results from the FEA validated the numerical strut were created; the spheres were placed on the two

results. The elastic moduli of around 10 GPa and the ends of the strut member, flushed to the edge of the inner

compression strength of 100–140 MPa attained from the wall where Boolean subtraction was performed. The

tests were within the ranges of that of the human bones. subtraction removed part of the flanges common with the

The correlations we established allow computational volume of the spheres.

Figure 1. Schematic of the horsetail-inspired lattice construction. (A) Location of parameters, (B) profile of extruded strut, and (C) cutting planes of strut

with Boolean subtraction of spheres on strut tips.

Volume 10 Issue 4 (2024) 189 doi: 10.36922/ijb.2326