Page 449 - IJB-10-4

P. 449

International Journal of Bioprinting Improving ductility of 3D-printed Zn–Mg

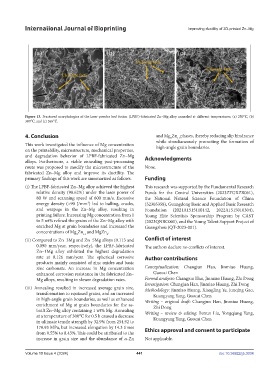

Figure 13. Fractured morphologies of the laser powder bed fusion (LPBF)-fabricated Zn–Mg alloy annealed at different temperatures: (a) 250℃, (b)

300℃, and (c) 365℃.

4. Conclusion and Mg Zn phases, thereby reducing slip hindrance

2

11

while simultaneously promoting the formation of

This work investigated the influence of Mg concentration high-angle grain boundaries.

on the printability, microstructure, mechanical properties,

and degradation behavior of LPBF-fabricated Zn–Mg Acknowledgments

alloys. Furthermore, a viable annealing post-processing

route was proposed to modify the microstructure of the None.

fabricated Zn–Mg alloy and improve its ductility. The

primary findings of this work are summarized as follows. Funding

(i) The LPBF-fabricated Zn–Mg alloy achieved the highest This research was supported by the Fundamental Research

relative density (98.62%) under the laser power of Funds for the Central Universities (2023ZYGXZR061),

80 W and scanning speed of 600 mm/s. Excessive the National Natural Science Foundation of China

energy density (>90 J/mm ) led to balling, cracks, (52305358), Guangdong Basic and Applied Basic Research

3

and warpage in the Zn–Mg alloy, resulting in Foundation (2021A1515110142, 2022A1515010304),

printing failure. Increasing Mg concentration from 1 Young Elite Scientists Sponsorship Program by CAST

to 5 wt% refined the grains of the Zn–Mg alloy with (2023QNRC001), and the Young Talent Support Project of

enriched Mg at grain boundaries and increased the Guangzhou (QT-2023-001).

concentrations of Mg Zn and MgZn .

2 11 2

(ii) Compared to Zn–3Mg and Zn–5Mg alloys (0.113 and Conflict of interest

0.090 mm/year, respectively), the LPBF-fabricated The authors declare no conflicts of interest.

Zn–1Mg alloy exhibited the highest degradation

rate at 0.126 mm/year. The spherical corrosive Author contributions

products mainly consisted of zinc oxides and basic

zinc carbonate. An increase in Mg concentration Conceptualization: Changjun Han, Jinmiao Huang,

enhanced corrosion resistance in the fabricated Zn– Guocai Chen

Mg alloys, resulting in slower degradation rates. Formal analysis: Changjun Han, Jinmiao Huang, Zhi Dong

Investigation: Changjun Han, Jinmiao Huang, Zhi Dong

(iii) Annealing resulted in increased average grain size, Methodology: Jinmiao Huang, Xiangling Ye, Junqing Gao,

transformation to equiaxed grains, and an increased Kuangyang Yang, Guocai Chen

in high-angle grain boundaries, as well as enhanced Writing – original draft: Changjun Han, Jinmiao Huang,

enrichment of Mg at grain boundaries for the as- Zhi Dong

built Zn–Mg alloy containing 1 wt% Mg. Annealing Writing – review & editing: Boxun Liu, Yongqiang Yang,

at a temperature of 300℃ for 0.5 h caused a decrease Kuangyang Yang, Guocai Chen

in ultimate tensile strength by 32.9% from 254.92 to

170.93 MPa, but increased elongation by 14.3 times Ethics approval and consent to participate

from 0.55% to 8.43%. This could be attributed to the

increase in grain size and the abundance of α-Zn Not applicable.

Volume 10 Issue 4 (2024) 441 doi: 10.36922/ijb.3034