Page 547 - IJB-10-4

P. 547

International Journal of Bioprinting 3D-bioprinting of osteochondral plugs

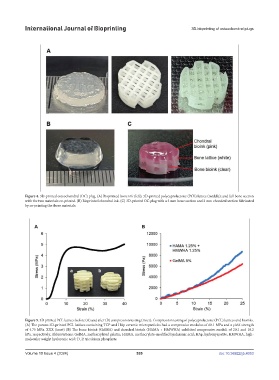

Figure 4. 3D-printed osteochondral (OC) plug. (A) Bioprinted bone ink (left); 3D-printed polycaprolactone (PCL) lattice (middle); and full bone section

with the two materials co-printed. (B) Bioprinted chondral ink. (C) 3D-printed OC plug with a 5 mm bone section and 2 mm chondral section fabricated

by co-printing the three materials.

Figure 5. 3D printed PCL lattices before (A) and after (B) compression testing (inset). Compression testing of polycaprolactone (PCL) lattices and bioinks.

(A) The porous 3D-printed PCL lattices containing TCP and HAp ceramic microparticles had a compressive modulus of 68.1 MPa and a yield strength

of 4.75 MPa. XXX (inset) (B) The bone bioink (GelMA) and chondral bioink (HAMA + HMWHA) exhibited compressive moduli of 20.1 and 18.2

kPa, respectively. Abbreviations: GelMA, methacrylated gelatin; HAMA, methacrylate-modified hyaluronic acid; HAp, hydroxyapatite; HMWHA, high-

molecular weight hyaluronic acid; TCP, tricalcium phosphate.

Volume 10 Issue 4 (2024) 539 doi: 10.36922/ijb.4053