Page 123 - IJB-5-1

P. 123

Hybrid polycaprolactone/hydrogel scaffold fabrication and in-process plasma treatment using PABS

A

B

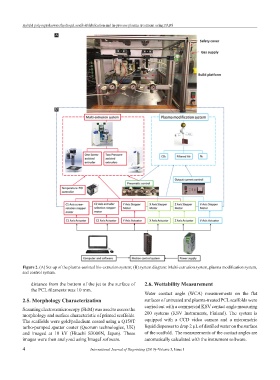

Figure 2. (A) Set-up of the plasma-assisted bio-extrusion system; (B) system diagram: Multi-extrusion system, plasma modification system,

and control system.

distance from the bottom of the jet to the surface of 2.6. Wettability Measurement

the PCL filaments was 10 mm.

Water contact angle (WCA) measurements on the flat

2.5. Morphology Characterization surfaces of untreated and plasma-treated PCL scaffolds were

carried out with a commercial KSV contact angle measuring

Scanning electron microscopy (SEM) was used to assess the

morphology and surface characteristic of printed scaffolds. 200 systems (KSV Instruments, Finland). The system is

The scaffolds were gold/palladium coated using a Q150T equipped with a CCD video camera and a micrometric

turbo-pumped sputter coater (Quorum technologies, UK) liquid dispenser to drop 2 µL of distilled water on the surface

and imaged at 10 kV (Hitachi S3000N, Japan). These of the scaffold. The measurements of the contact angles are

images were then analyzed using ImageJ software. automatically calculated with the instrument software.

4 International Journal of Bioprinting (2019)–Volume 5, Issue 1