Page 272 - IJB-10-5

P. 272

International Journal of Bioprinting A TPMS framework for complete dentures

Table 5. Selective laser melting (SLM) processing parameters for Ti6Al4V alloy powder

Laser power (W) Scanning speed (mm/s) Spot size (μm) Layer thickness (μm) Hatch spacing (μm)

150 650 100 60 60

Parameter Specification

Laser power (W) 150

Scanning speed (mm/s) 650

Spot size (µm) 100

Layer thickness (µm) 60

Hatch spacing (µm) 60

An electronic analytical balance and a vernier caliper

were used to measure the weight and size of the static

compression test samples, respectively. Based on the

measurements, the relative density of the samples was

then calculated using the weighing method to evaluate

printing accuracy.

The surface morphology of the samples was obtained

using scanning electron microscopy (SEM; Zeiss Sigma

300; Zeiss, Germany). Subsequently, the samples were

subjected to grinding and polishing to observe micro-

pores and microstructures. The grinding process was

conducted using an automatic polishing machine, followed

by multiple polishing steps using different sandpapers

(#2000, #2500, and #3000) to achieve a mirror-like finish.

The samples were etched for ~60 s using a Kroll etchant

to expose the microstructure, then observed using

an ultra-depth 3D microscope (Keyence VHX-7000;

Keyence, Japan).

Teeth experience a wide range of complex forces during

daily occlusal activities, including axial occlusal and

lateral forces. Therefore, porous frameworks must possess

adequate yield and flexural strength. In this regard, static

compression, three-point bending, and impact experiments

were conducted to assess the mechanical performance of

samples, ensuring that the IFCD framework meets the

usage requirements.

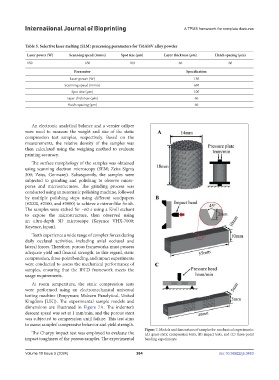

At room temperature, the static compression tests

were performed using an electromechanical universal

testing machine (Empyrean; Malvern Panalytical, United

Kingdom [UK]). The experimental sample models and

dimensions are illustrated in Figure 7A. The indenter’s

descent speed was set at 1 mm/min, and the porous stent

was subjected to compression until failure. This test aims

to assess samples’ compressive behavior and yield strength.

Figure 7. Models and dimensions of samples for mechanical experiments:

The Charpy impact test was employed to evaluate the (A) quasi-static compression tests, (B) impact tests, and (C) three-point

impact toughness of the porous samples. The experimental bending experiments.

Volume 10 Issue 5 (2024) 264 doi: 10.36922/ijb.3453