Page 262 - IJB-10-6

P. 262

International Journal of Bioprinting 3D-printed contractive pennate muscle

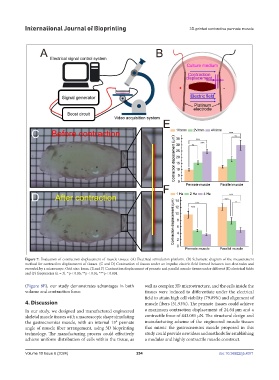

Figure 7. Evaluation of contraction displacement of muscle tissues. (A) Electrical stimulation platform. (B) Schematic diagram of the measurement

method for contraction displacement of tissues. (C and D) Contraction of tissues under an impulse electric field formed between two electrodes and

recorded by a microscope. Grid size: 1mm. (E and F) Contraction displacement of pennate and parallel muscle tissues under different (E) electrical fields

and (F) frequencies (n = 3). *p < 0.05; **p < 0.01; ***p < 0.001.

(Figure 8E), our study demonstrates advantages in both well as complex 3D microstructure, and the cells inside the

volume and contraction force. tissues were induced to differentiate under the electrical

field to attain high cell viability (79.89%) and alignment of

4. Discussion muscle fibers (51.93%). The pennate tissues could achieve

In our study, we designed and manufactured engineered a maximum contraction displacement of 24.64 μm and a

skeletal muscle tissues with a macroscopic shape simulating contractile force of 443.085 μN. The structural design and

the gastrocnemius muscle, with an internal 15° pennate manufacturing scheme of the engineered muscle tissues

angle of muscle fiber arrangement, using 3D bioprinting that mimic the gastrocnemius muscle proposed in this

technology. The manufacturing process could effectively study could provide new ideas and methods for establishing

achieve uniform distribution of cells within the tissue, as a modular and highly contractile muscle construct.

Volume 10 Issue 6 (2024) 254 doi: 10.36922/ijb.4371