Page 577 - IJB-10-6

P. 577

International Journal of Bioprinting Biomechanical analysis of mandibular implants

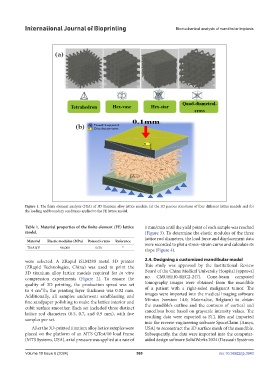

Figure 1. The finite element analysis (FEA) of 3D titanium alloy lattice models: (a) the 3D porous structures of four different lattice models and (b)

the loading and boundary conditions applied to the FE lattice model.

Table 1. Material properties of the finite element (FE) lattice 1 mm/min until the yield point of each sample was reached

model. (Figure 3). To determine the elastic modulus of the three

lattice rod diameters, the load force and displacement data

Material Elastic modulus (MPa) Poisson’s ratio Reference were recorded to plot a stress–strain curve and calculate its

Ti6Al4V 96,000 0.36 21

slope (Figure 4).

were selected. A ZRapid iSLM280 metal 3D printer 2.4. Designing a customized mandibular model

(ZRapid Technologies, China) was used to print the This study was approved by the Institutional Review

3D titanium alloy lattice models required for in vitro Board of the China Medical University Hospital (approval

compression experiments (Figure 2). To ensure the no. CMUH110-REC2-247). Cone-beam computed

quality of 3D printing, the production speed was set tomography images were obtained from the mandible

to 4 cm³/h; the printing layer thickness was 0.02 mm. of a patient with a right-sided malignant tumor. The

Additionally, all samples underwent sandblasting and images were imported into the medical imaging software

fine sandpaper polishing to make the lattice interior and Mimics (version 14.0; Materialise, Belgium) to obtain

cubit surface smoother. Each set included three distinct the mandible’s outline and the contours of cortical and

cancellous bone based on grayscale intensity values. The

lattice rod diameters (0.5, 0.7, and 0.9 mm), with five resulting data were exported as STL files and imported

samples per set.

into the reverse-engineering software SpaceClaim (Ansys,

After the 3D-printed titanium alloy lattice samples were USA) to reconstruct the 3D surface mesh of the mandible.

placed on the platform of an MTS QTest/10 load frame Subsequently, the data were imported into the computer-

(MTS Systems, USA), axial pressure was applied at a rate of aided design software SolidWorks 2024 (Dassault Systèmes

Volume 10 Issue 6 (2024) 569 doi: 10.36922/ijb.3943