Page 19 - IJB-7-1

P. 19

Zhang, et al.

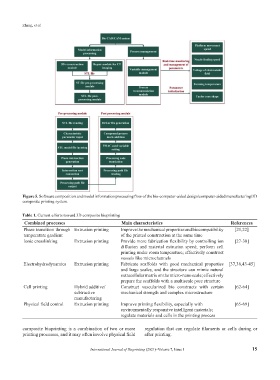

Figure 5. Software composition and model information processing flow of the bio-computer-aided design/computer-aided manufacturing/3D

composite printing system.

Table 1. Current efforts toward 3D composite bioprinting

Combined processes Main characteristics References

Phase transition through Extrusion printing Improve the mechanical properties and biocompatibility [21,22]

temperature gradient of the printed construction at the same time

Ionic crosslinking Extrusion printing Provide more fabrication flexibility by controlling ion [27-30]

diffusion and material extrusion speed; perform cell

printing under room temperature; effectively construct

vessels like microchannels

Electrohydrodynamics Extrusion printing Fabricate scaffolds with good mechanical properties [37,38,43-45]

and large scales, and the structure can mimic natural

extracellular matrix on the micro-nano scale; effectively

prepare the scaffolds with a multiscale pore structure

Cell printing Hybrid additive/ Construct vascularized bio constructs with certain [62-64]

subtractive mechanical strength and complex microstructure

manufacturing

Physical field control Extrusion printing Improve printing flexibility, especially with [65-69]

environmentally responsive intelligent materials;

regulate materials and cells in the printing process

composite bioprinting is a combination of two or more regulation that can regulate filaments or cells during or

printing processes, and it may often involve physical field after printing.

International Journal of Bioprinting (2021)–Volume 7, Issue 1 15