Page 31 - IJB-7-1

P. 31

Attarilar, et al.

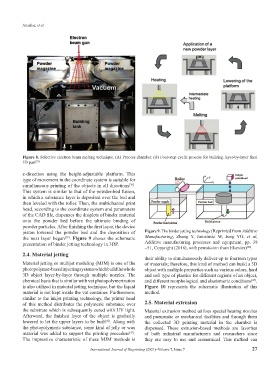

Figure 8. Selective electron beam melting technique. (A) Process chamber. (B) Four-step cyclic process for building layer-by-layer final

3D part [37]

z-direction using the height-adjustable platform. This

type of movement in the coordinate system is suitable for

simultaneous printing of the objects in all directions .

[38]

This system is similar to that of the powder-bed fusion,

in which a substance layer is deposited over the bed and

then leveled with the roller. Then, the multichannel print

head, according to the coordinate system and parameters

of the CAD file, dispenses the droplets of binder material

onto the powder bed before the ultimate binding of

powder particles. After finishing the first layer, the device

piston lowered the powder bed and the deposition of Figure 9. The binder jetting technology (Reprinted from Additive

the next layer began . Figure 9 shows the schematic Manufacturing, Zhang Y, Jarosinski W, Jung YG, et al,

[39]

presentation of binder jetting technology in 3DP. Additive manufacturing processes and equipment, pp. 39

–51, Copyright (2018), with permission from Elsevier) .

[40]

2.4. Material jetting

their ability to simultaneously deliver up to fourteen types

Material jetting or multijet modeling (MJM) is one of the of materials; therefore, this kind of method can build a 3D

photopolymer-based injecting systems which build the whole object with multiple properties such as various colors, hard

3D object layer-by-layer through multiple nozzles. The and soft type of plastics for different regions of an object,

chemical basis that is similar with vat photopolymerization and different morphological and elastomeric conditions .

[43]

is also utilized in material jetting technique, but the liquid Figure 10 represents the schematic illustration of this

material is not kept inside the vat container. Furthermore, method.

similar to the inkjet printing technology, the printer head

of this method distributes the polymeric substance over 2.5. Material extrusion

the substrate which is subsequently cured with UV light. Material extrusion method utilizes special heating nozzles

Afterward, the finished layer of the object is gradually and pneumatic or mechanical facilities and through them

lowered to let the upper layers to be built . Along with the collected 3D printing material in the chamber is

[41]

the photopolymeric substance, some kind of jelly or wax dispensed. These extrusion-based methods are favorites

material was added to support the printing procedure . of both industrial manufacturers and researchers since

[42]

The impressive characteristic of these MJM methods is they are easy to use and economical. This method can

International Journal of Bioprinting (2021)–Volume 7, Issue 7 27