Page 79 - IJB-7-1

P. 79

Jing, et al.

A B C D E

F G H I J

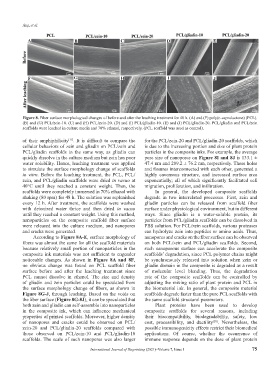

Figure 8. Fiber surface morphological changes of before and after the leaching treatment for 48 h. (A) and (F) poly(ε-caprolactone) (PCL).

(B) and (G) PCL/zein-10. (C) and (H) PCL/zein-20. (D) and (I) PCL/gliadin-10. (E) and (J) PCL/gliadin-20. PCL/gliadin and PCL/zein

scaffolds were leached in culture media and 70% ethanol, respectively. (PCL scaffold was used as control).

of their amphiphilicity . It is difficult to compare the for the PCL/zein-20 and PCL/gliadin-20 scaffolds, which

[17]

cellular behaviors of zein and gliadin on PCL/zein and is due to the increasing portion and size of plant protein

PCL/gliadin scaffolds in the same way, as gliadin can particles in the composite inks. For example, the average

quickly dissolve in the culture medium but zein has poor pore size of nanopores on Figure 8I and 8J is 133.1 ±

water solubility. Hence, leaching treatment was applied 47.4 nm and 209.2 ± 76.2 nm, respectively. These holes

to simulate the surface morphology change of scaffolds and fissures interconnected with each other, generated a

in vitro. Before the leaching treatment, the PCL, PCL/ highly cavernous structure, and increased surface area

zein, and PCL/gliadin scaffolds were dried in vacuo at exponentially; all of which significantly facilitated cell

40°C until they reached a constant weight. Then, the migration, proliferation, and infiltration.

scaffolds were completely immersed in 70% ethanol with In general, the developed composite scaffolds

shaking (80 rpm) for 48 h. The solution was replenished degrade in two interrelated processes. First, zein and

every 12 h. After treatment, the scaffolds were washed gliadin particles can be released from scaffold fiber

with deionized water thrice and then dried in vacuo surface under physiological environment, but in different

until they reached a constant weight. Using this method, ways. Since gliadin is a water-soluble protein, its

nanoparticles on the composite scaffold fiber surface particles from PCL/gliadin scaffolds can be dissolved in

were released into the culture medium, and nanopores PBS solution. For PCL/zein scaffolds, various proteases

and cracks were generated. can hydrolyze zein into peptides or amino acids. Thus,

According to Figure 8A-E, surface morphology of nanopores and cracks on the fiber surface can be observed

fibers was almost the same for all the scaffold materials on both PCL/zein and PCL/gliadin scaffolds. Second,

because relatively small portion of nanoparticles in the such nanoporous surface can accelerate the composite

composite ink materials was not sufficient to engender scaffolds’ degradation, since PCL polymer chains might

noticeable changes. As shown in Figure 8A and 8F, be synchronously released into solution when zein or

no obvious change was found on PCL scaffold fiber gliadin domain in the composite is degraded as a result

surface before and after the leaching treatment since of molecular level blending. Thus, the degradation

PCL cannot dissolve in ethanol. The size and density rate of the composite scaffolds can be controlled by

of gliadin and zein particles could be speculated from adjusting the mixing ratio of plant protein and PCL in

the surface morphology change of fibers, as shown in the biomaterial ink. In general, the composite material

Figure 8G-J, through leaching. Based on the voids on scaffolds degrade faster than the pure PCL scaffolds with

the fiber surface (Figure 8G-8J), it can be speculated that the same scaffold structural parameters.

both zein and gliadin can self-assemble into nanoparticles Plant proteins have been used to develop

in the composite ink, which can influence mechanical composite scaffolds for several reasons, including

properties of printed scaffolds. Moreover, higher density their biocompatibility, biodegradability, safety, low

of nanopores and cracks could be observed on PCL/ cost, processibility, and ductility . Nevertheless, the

[28]

zein-20 and PCL/gliadin-20 scaffolds compared with possible immunogenicity effects restrict their biomedical

those observed on PCL/zein-10 and PCL/gliadin-10 applications. Of course, whether the occurrence of

scaffolds. The scale of such nanopores was also larger immune response depends on the dose of plant protein

International Journal of Bioprinting (2021)–Volume 7, Issue 1 75