Page 159 - IJB-7-3

P. 159

Al-Tamimi

independent filtering and sensitivity filtering to prevent screw holes, six-screw holes, and eight-screw holes) were

checkerboarding) along the design domain. designed using Solidworks (Dassault Systèmes, France)

with a length of 180 mm, width of 14 mm, and thickness

3. Simulation and optimization of 5 mm (Table 1). Abaqus (Dassault Systèmes, France)

was used to perform the TO and finite element analysis.

3.1. Initial design domains Plates were considered to be made with Ti-6Al-4V (120

The DePuy Synthes narrow LCP, commonly used for the GPa of Elastic Modulus and 0.3 of Poisson’s ratio).

treatment of long bones such as humerus, femur, and tibia, Finite element meshes were created using eight-node

was considered as a reference design. Three plates (four- linear hexahedral elements and approximately 400,000

elements were considered. Different mesh densities were

also considered for the mesh dependency study.

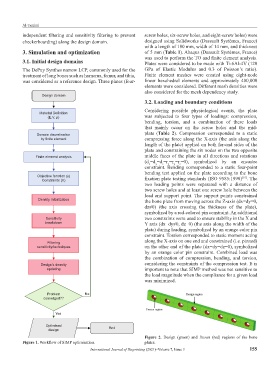

Design domain

3.2. Loading and boundary conditions

Considering possible physiological events, the plate

Material Definition

(E,V, ρ) was subjected to four types of loadings: compression,

bending, torsion, and a combination of these loads

that mainly occur on the screw holes and the mid-

Domain discretisation plate (Table 2). Compression corresponded to a static

by finite element compressing force along the X-axis (the axis along the

length of the plate) applied on both far-end sides of the

plate and constraining the six nodes on the two opposite

Finite element analysis middle faces of the plate in all directions and rotations

(d =d =d =r =r =r =0), symbolized by an encastre

y

x

z

y

z

x

constraint. Bending corresponded to a static four-point

bending test applied on the plate according to the bone

Objective function (ε) [15]

Constraints (V) fixation plate testing standards (ISO 9585:1990) . The

two loading points were separated with a distance of

two screw holes and at least one screw hole between the

load and support point. The support points constrained

Density initialization the bone plate from moving across the Z-axis (dx=dy=0,

dz≠0) (the axis crossing the thickness of the plate),

symbolized by a red-colored pin constraint. An additional

Sensitivity two constraints were used to ensure stability in the X and

breakdown Y axis (dx=dy≠0, dz=0) (the axis along the width of the

plate) during loading, symbolized by an orange color pin

constraint. Torsion corresponded to static moment acting

Filtering along the X-axis on one end and constrained (i.e. pinned)

sensitivity/techniques on the other end of the plate (dx=dy=dz=0), symbolized

by an orange color pin constraint. Combined load was

the combination of compression, bending, and torsion,

Design’s density considering the constraints of the compression test. It is

updating important to note that SIMP method was not sensitive to

the load magnitude when the compliance for a given load

was minimized.

Problem No

converged??

Yes

Optimised

design End

Figure 2. Design (green) and frozen (red) regions of the bone

Figure 1. Workflow of SIMP optimisation. plates.

International Journal of Bioprinting (2021)–Volume 7, Issue 3 155